Reflectivity of vitrinite and the degree of catagenesis. Vitrinite group Influence of ash content of coals on the reflectance of vitrinite

page 1

page 2

p. 3

page 4

p. 5

page 6

page 7

page 8

page 9

p. 10

page 11

p. 12

p. 13

p. 14

p. 15

page 16

p. 17

p. 18

p. 19

FEDERAL AGENCY FOR TECHNICAL REGULATION AND METROLOGY

THE NATIONAL

STANDARD

RUSSIAN

FEDERATIONS

MEDICAL PRODUCTS FOR DIAGNOSTICS

IN VITRO

Information provided by the manufacturer with in vitro diagnostic reagents for biological staining

In vitro diagnostic medical devices - Information supplied by the manufacturer with in vitro diagnostic reagents for staining in biology (IDT)

Official edition

Standardinform

Foreword

The goals and principles of standardization in the Russian Federation are established Federal law of December 27, 2002 No. 184-FZ "On technical regulation", and the rules for the application of national standards of the Russian Federation - GOST R 1.0-2004 "Standardization in the Russian Federation. Basic provisions "

Information about the standard

1 PREPARED by the Laboratory of Problems of Clinical and Laboratory Diagnostics of the Research Institute of Public Health and Healthcare Management of the State Budgetary Educational Institution of Higher vocational education First Moscow State Medical University. I. M. Sechenov "of the Ministry of Health of the Russian Federation on the basis of its own authentic translation into Russian international standard specified in paragraph 4

2 INTRODUCED by the Technical Committee for Standardization TC 380 "Clinical laboratory research and medical devices for in vitro diagnostics"

3 APPROVED AND INTRODUCED BY Order Federal agency on technical regulation and metrology dated October 25, 2013 No. 1201-st.

4 This standard identical to the international standard ISO 19001: 2002 “Medical devices for in vitro diagnostics. Information supplied by the manufacturer with in vitro diagnostic reagents for staining in biology ”(ISO 19001: 2002“ / l vitro diagnostic medical devices - Information supplied by the manufacturer with in vitro diagnostic reagents for staining in biology ”).

The name of this standard has been changed from the name of the specified international standard to bring it into line with GOST R 1.5 (subsection 3.5).

5 INTRODUCED FOR THE FIRST TIME

The rules for the application of this standard are established in GOST R 1.0-2012 (section 8). Information on changes to this standard is published in the annually published information index "National Standards", and the text of changes and amendments - in the monthly published information indexes "National Standards". In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly published information index "National Standards". Relevant information, notice and texts are also posted in the information system. common use- on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet (gost.ru)

© Standartinform, 2014

This standard may not be reproduced in whole or in part, replicated and distributed as an official publication without permission from the Federal Agency for Technical Regulation and Metrology.

A.4.2.3.3 Staining procedure

А.4.2.3.3.1 Dewax and rehydrate tissue sections; carry out an antigen change (see the above staining method)

A.4.2.3.3.2 Incubate with hydrogen peroxide. mass fraction 3% in distilled water for 5

A.4.2.3.3.3 Rinse with distilled water and place in TBS for 5 min.

A.4.2.3.3.4 Incubate with monoclonal mouse anti-human estrogen receptor, optimally diluted in TBS (see A.4.2.3), for 20 to 30 min.

A.4.2.3.3.5 Wash with TBS and place in the TBS bath for 5 min.

A.4.2.3.3.6 Incubate with the working solution of biotinylated goat antibodies to mouse / rabbit immunoglobulins for 20 to 30 min.

A.4.2.3.3.7 Wash with TBS and place in the TBS bath for 5 min.

А.4.2.3.3.8 Incubate with the working solution of the StreptAvidin-biotin / horseradish peroxidase complex for 20 - 30 min.

A.4.2.3.3.9 Wash with TBS and place in the TBS bath for 5 min.

A.4.2.3.3.10 Incubate with DAB solution for 5-15 min (use gloves when handling DAB).

A4.2.3.3.11 Rinse with distilled water.

А.4.2.3.3.12 Conduct counterstaining with hematoxylin solution for 30 s.

A.4.2.3.3.13 Rinse with tap water for 5 min.

A.4.2.3.3.14 Rinse with distilled water for 5 min.

A.4.2.3.3.15 Dehydrate with ethanol 50% v / v for 3 min, then 3 min with 70% v / v and finally 3 min with 99% v / v.

A.4.2.3.3.16 Rinse in two xylene changes, 5 min each. A.4.2.3.3.17 Extract into synthetic hydrophobic resin.

A.4.2.3.4 Suggested dilutions

Optimal staining can be obtained by diluting the antibody in TBS at pH = 7.6, mixed in volume from (1 + 50) to (1 + 75) μL when examined on formalin-fixed paraffin-embedded human breast cancer sections. The antibody can be diluted with TBS, mixed in volumes from (1 + 50) to (1 + 100) μl, for use in APAAP technology and avidin-biotin methods, in the study of acetone-fixed sections of frozen breast cancer tissue.

A.4.2.3.5 Expected results

The antibody intensely marks the nuclei of cells known to contain a large number of estrogen receptors, for example, epithelial and myometrial cells of the uterus and normal and hyperplastic mammary epithelial cells. The staining is predominantly localized in the nuclei without staining the cytoplasm. However, cryostat slices containing small or undetectable amounts of estrogen receptors (eg, intestinal epithelium, heart muscle cells, brain cells, and connective tissue) are negative with antibody. The antibody labels breast carcinoma epithelial cells that express the estrogen receptor.

Fabric dyeing depends on the handling and processing of the fabric prior to dyeing. Improper fixation, freezing, thawing, rinsing, drying, heating, cutting, or contamination with other tissues or fluids can cause artifacts or false negative results.

A.5 Demonstration of 7-cells by flow cytometry

CAUTION - The reagent contains sodium azide (15 mmol / L). NaN 3 can react with lead or copper to form explosive metal azides. When removing, wash off with plenty of water.

A.5.1 Monoclonal mouse anti-human G-pads

The following information applies to monoclonal mouse anti-human 7-pets:

a) product identity: monoclonal mouse anti-human 7-pet, CD3;

b) clone: UCHT;

c) immunogen: human infant thymocytes and lymphocytes from a patient with Sezary disease;

d) source of antibodies: purified monoclonal mouse antibodies;

e) specificity: the antibody reacts with T cells in the thymus, bone marrow, peripheral lymphoid tissue and blood. Most tumor T cells also express the CD3 antigen, but it is absent in non-T cell lymphoid tumors. Consistent with the model of antigen synthesis in normal thymocytes, the earliest detection site in tumor cells is the cytoplasm of the cell;

f) composition:

0.05 mol / L Tris / HCI buffer, 15 mmol / L NaN 3, pH = 7.2, bovine serum albumin, mass fraction 1

Lg isotype: IgGI;

Purification of lg: Protein A Sepharose column;

Purity: mass fraction about 95%;

Conjugate molecule: fluorescein isothiocyanate isomer 1 (FITC);

- (NR) -relation: £ 495 nm / £ 278 nm = 1.0 ± 0.1 corresponding to the FITC / protein molar ratio of about 5;

e) handling and storage: stable for three years after isolation at a temperature of 2 ° C to 8

A.5.2 Intended use

A.5.2.1 General

The antibody is intended for use in flow cytometry. The antibody can be used for the qualitative and quantitative detection of T cells.

A.5.2.2 Type (s) of material

The antibody can be applied to suspensions of fresh and fixed cells, acetone-fixed cryostat sections, and cell smears.

A.5.2.3 Test procedure for antibody reactivity for flow cytometry

The details of the procedure used by the manufacturer are as follows:

a) Collect venous blood into a test tube containing an anticoagulant.

b) Isolate mononuclear cells by centrifugation on a separation medium; otherwise, the erythrocytes are lysed after the incubation step indicated in d).

c) Wash mononuclear cells twice with RPMI 1640 or phosphate buffered saline (PBS) (0.1 mol / L phosphate, 0.15 mol / L NaCl, pH = 7.4).

d) To 10 μl of FITC-conjugated monoclonal mouse anti-human T cells, CD3 reagent, add a cell suspension containing 1-10 e cells (usually about 100 ml) and mix. Incubate in the dark at 4 ° C for 30 min [for double staining at the same time, R-phycoerythrin-conjugated antibody (RPE) must be added].

f) Washed twice with PBS + 2% bovine serum albumin; resuspend the cells in an appropriate fluid for analysis on a flow cytometer.

f) Use a different monoclonal antibody conjugated with FITC (fluorescein isothiocyanate) as negative control

e) The precipitated cells are fixed by stirring with 0.3 ml of paraformaldehyde by mass fraction of 1% in PBS. When stored in the dark at 4 ° C, fixed cells can be kept for up to two weeks.

h) Analyze on a flow cytometer.

A.5.2.4 Suggested dilution

The antibody should be used for flow cytometry in a concentrated form (10 μl / gest). For use on cryostat slices and cell smears, the antibody must be mixed with a suitable diluent in a volume ratio of (1 + 50) µl.

A.5.2.5 Expected results

The antibody detects a CD3 molecule on the surface of the T-cells. When evaluating staining of cryostat sections and cell smears, the reaction product should be localized on the plasma membrane.

Fabric dyeing depends on the handling and processing of the fabric prior to dyeing. Improper fixation, freezing, thawing, washing, drying, heating, sectioning, or contamination with other tissues or fluids can cause artifacts or false negative results.

Appendix YES (reference)

Information on the compliance of the referenced international and European regional standards with the national standards of the Russian Federation

|

Table YES.1 |

||||||||||||||||||||||||

|

||||||||||||||||||||||||

NATIONAL STANDARD OF THE RUSSIAN FEDERATION

MEDICAL EQUIPMENT FOR IN VITRO DIAGNOSTICS Information provided by the manufacturer with in vitro diagnostic reagents used for staining in biology

In vitro diagnostic medical devices. Information supplied by the manufacturer with in vitro diagnostic reagents for staining in biology

Date of introduction - 2014-08-01

1 area of use

This International Standard specifies requirements for information provided by manufacturers on reagents used for staining in biology. The requirements apply to manufacturers, suppliers and sellers of dyes, paints, chromogenic reagents and other reagents used for staining in biology. The requirements for information provided by manufacturers specified in this standard are necessary condition obtaining comparable and reproducible results in all areas of staining in biology.

This standard uses normative references to the following international and European regional standards:

ISO 31-8, Quantities and units. Part 8. Physical chemistry and molecular physics (ISO 31-8, Quantities and units - Part 8: Physical chemistry and molecular physics)

EH 375: 2001 Information supplied by the manufacturer with in vitro diagnostic reagents for professional use

EH 376: 2001 Information supplied by the manufacturer with in vitro diagnostic reagents for self-testing

Note - When using this standard, it is advisable to check the validity of the reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or according to the annual information index "National Standards", which was published as of January 1 of the current year, and on the issues of the monthly information index "National Standards" for the current year. If the referenced standard to which an undated reference is given is replaced, it is recommended that the current version of that standard be used, subject to any changes made to that version. If the referenced standard to which the dated reference is given is replaced, it is recommended to use the version of that standard with the above year of approval (acceptance). If, after the approval of this standard, a change is made to the referenced standard to which the dated reference is given, affecting the provision to which the reference is made, then that provision is recommended to be applied without taking into account that change. If the reference standard is canceled without replacement, then the provision in which the reference to it is given is recommended to be applied in the part that does not affect this reference.

3 Terms and definitions

The following terms are used in this standard with the corresponding definitions:

3.1 information supplied by the manufacturerall printed, written, graphic or other information supplied with or accompanying an IVD reagent

3.2 labelany printed, written or graphic information on a package

Official edition

3.3 in vitro diagnostic reagentreagent used alone or in combination with other in vitro diagnostic medical devices intended by the manufacturer for in vitro studies of substances of human, animal or plant origin in order to obtain information related to the detection, diagnosing, monitoring or treating physiological conditions, health conditions or disease or congenital anomaly.

3.4 stainingcolouring of a material by reaction with a dye or chromogenic reagent

3.5 dye dyed organic compound which, when dissolved in a suitable solvent, is capable of imparting color to a material

NOTE The physical nature of color is selective absorption (and / or emission) in the visible region of the electromagnetic spectrum between 400 and 800 nm. Dyes are molecules with large systems of delocalized electrons (bound TT-electron systems). The light absorption characteristics of colorants are represented by an absorption spectrum in the form of a diagram that compares light absorption and wavelength. The spectrum and wavelength at maximum absorption depend on the chemical structure of the colorant, solvent and spectral measurement conditions.

3.6 dye

NOTE The paint can be prepared by directly dissolving the colorant in a solvent or by diluting the finished stock solution with suitable agents.

3.6.1 stock solution of stainstable, defined solution of one or more dyes at a higher concentration than that used for dyeing

NOTE Stability means the consistency of the properties of a colorant even in the presence of other colorants.

3.7 chromogenic reagentreagent that reacts with chemical groups present or evoked in cells and tissues to form a colored compound in situ

EXAMPLE Typical chromogenic reagents:

a) diazonium salt;

b) Schiff's reagent.

3.8 fluorochromereagent that emits visible light when irradiated with excitation light of a shorter wavelength

3.9 antibody specific immunoglobulin produced by B-lymphocytes in response to exposure to an immunogenic substance and capable of binding to it

Note - A molecule of an immunogenic substance contains one or more parts with a characteristic chemical composition, an epitope.

3.9.1 polyclonal antibodymixture of antibodies capable of reacting specifically with a specified immunogenic substance

3.9.2 monoclonal antibodyAntibody capable of reacting specifically with a single epitope of a specified immunogenic substance

3.10 nucleic acid probeSingle stranded oligonucleotide or polynucleotide of a specified length, complementary to a specific nucleotide sequence of nucleic acids

3.11 lectin: A non-immunogenic protein with two or more binding sites that recognizes and binds to specific saccharide residues.

4 Requirements for information supplied by the manufacturer

4.1 General requirements

4.1.1 Information provided by the manufacturer with reagents used for staining in biology

The information provided by the manufacturer with reagents used for staining in biology should be in accordance with ISO 31-8, ISO 1000, EN 375 and EN 376. Particular attention should be paid to the warnings given in EN 375. In addition, if applicable, the requirements specified in 4.1.2, 4.1.3 and 4.1.4 should be applied to the various reagents used for staining in biology.

4.1.2 Product name

The product name must include the CAS registration number and the colorant name and index number, if applicable.

Note1- CAS registration numbers are CAS registration numbers. They represent the numerical code numbers of the substances assigned to the chemical substances, which have received the index in the Chemical Reference Service.

NOTE 2 The ink index gives a 5-digit number, C.I. and a specially compiled name for most of the dyes.

4.1.3 Reagent Description

The description of the reagent should include the relevant physicochemical data, accompanied by information specific to each batch. The data must contain at least the following information:

a) molecular formula, including counterion;

b) molar mass (g / mol) precisely indicated, with or without the inclusion of a counter ion;

c) acceptable limits for interfering substances;

For colored organic compounds, the data should contain:

d) molar absorption (instead, the content of the molecule of the pure colorant may be given, but not the content of the total colorant);

e) wavelength or number of waves at maximum absorption;

f) data from thin layer chromatography, high performance liquid chromatography or high performance thin layer chromatography.

4.1.4 Intended use

A description should be provided providing guidance on staining in biology and quantitative and qualitative procedures (if applicable). Information should include details of the following:

a) type (s) of biological material, handling and treatment prior to staining, for example:

1) whether cell or tissue samples can be used;

2) whether frozen or chemically fixed material can be used;

3) protocol for tissue handling;

4) what kind of fixing medium can be applied;

b) details of the appropriate reaction procedure used by the manufacturer to investigate the reactivity of a dye, dye, chromogenic reagent, fluorochrome, antibody, nucleic acid probe or lectin used for staining in biology;

c) the result (s) expected from the response procedure on the intended type (s) of material in the manner specified by the manufacturer;

d) remarks on suitable positive or negative tissue controls and on the interpretation of the result (s);

4.2 Additional requirements for specific types of reagents

4.2.1 Fluorochromes

Regardless of the type of application, fluorochromes proposed for staining in biology must be accompanied by the following information:

a) selectivity, such as describing the target (s) that can be demonstrated using specific conditions; wavelengths of excitation and emission light; for fluorochromes associated with antibodies, the ratio of fluorochrome / protein (F / B).

4.2.2 Metal salts

Where metal-containing compounds are proposed for use in metal-absorbing techniques for staining in biology, the following additional information should be provided:

systematic name; purity (no impurities).

4.2.3 Antibodies

Antibodies proposed for staining in biology must be accompanied by the following information:

a) a description of the antigen (immunogenic substance) against which the antibody is directed and, if the antigen is determined by the cluster of the differentiation system, the CD number. The description should contain, if appropriate, the type of macromolecule detected, a part of which is to be found, the cellular localization and the cells or tissues in which it is located, and any cross-reactivity with other epitopes;

b) for monoclonal antibodies, clone, method of formation (tissue culture supernatant or ascitic fluid), immunoglobulin subclass and light chain identity;

c) for polyclonal antibodies, the host animal, and whether whole serum or an immunoglobulin fraction is used;

a description of the form (solution or lyophilized powder), the amount of total protein and specific antibody, and for the solution - the nature and concentration of the solvent or medium;

e) if applicable, a description of any molecular binders or excipients added to the antibody;

a statement of purity, purification technique, and detection methods for impurities (eg, Western blotting, immunohistochemistry);

4.2.4 Nucleic acid probes

Nucleic acid probes proposed for biology staining must be accompanied by the following information:

the sequence of bases and is the probe one - or two-helical; the molar mass of the probe or the number of bases and, if applicable, the number of fractions (in percent) of guanine-cytosine base pairs;

used marker (radioactive isotope or non-radioactive molecule), the point of attachment to the probe (3 "and / or 5") and the percentage of the substance in the percentage of the labeled probe; detectable gene target (DNA or RNA sequence);

e) a description of the form (lyophilized powder or solution) and the amount (pg or pmol) or concentration (pg / ml or pmol / ml), if applicable, and, in the case of a solution, the nature and concentration of the solvent or medium;

f) a statement of purity, purification procedures and detection methods for impurities, eg high performance liquid chromatography;

Appendix A (informative)

Examples of information provided by the manufacturer with reagents commonly used

in biological staining techniques

A.1 General

The following information provides examples of procedures and should not be construed as the only way a procedure should be carried out. These procedures can be used by the manufacturer to investigate the reactivity of colorants and illustrate how the manufacturer can provide information to comply with this International Standard.

A.2 Methyl green dye-pyronine Y A.2.1 Methyl green dye

The information regarding the dye methyl green is as follows:

a) product identity:

Methyl green (synonyms: SF double green, light green);

CAS Registration Number: 22383-16-0;

Color name and index number: basic blue 20, 42585;

b) composition:

Molecular formula including counterion: C 2 bNZM 3 2 + 2BF4 ";

Molar mass with (or without) counterion: 561.17 g mol "1 (387.56 g

Mass fraction (content) of methyl green cation: 85%, determined using absorption spectrometry;

Allowable limits for interfering substances, given as mass fractions:

1) water: less than 1%;

2) inorganic salts: less than 0.1%;

3) detergents: not present;

4) colored impurities, including violet crystals: not detectable by thin layer chromatography;

5) indifferent compounds: 14% soluble starch;

d) thin layer chromatography: only one main component is present, corresponding

methyl green;

e) Handling and storage: Stable when stored in a carefully sealed brown bottle at room temperature (18 ° C to 28 ° C).

A.2.2 Coloring substance ethyl green

The information related to the dye ethyl green is as follows:

a) product identity:

1) ethyl green (synonym: methyl green);

2) CAS registration number: 7114-03-6;

3) the name and number of the paint index: the name is absent in the paint index, 42590;

b) composition:

1) molecular formula including counterion: C27H 3 5N 3 2+ 2 BF4 ";

2) molar mass with (or without) counterion: 575.19 g mol "1 (401.58 g mol" 1);

3) mass fraction of ethyl green cation: 85%, determined by absorption spectrometry;

Water: less than 1%;

Detergents: absent;

c) wavelength of maximum absorption of the dye solution: 633 nm;

d) thin layer chromatography: there is only one major component, coincident with ethyl green;

A.2.3 Coloring substance pyronine Y

The following information applies to the dye pyronine Y:

a) product identity:

1) pyronine Y (synonyms: pyronine Y, pyronine G, pyronine G);

2) CAS registration number: 92-32-0;

3) name and number in the ink index: there is no name in the ink index, 45005;

b) composition:

1) molecular formula including counterion: Ci7HigN20 + SG;

2) molar mass with (or without) counterion: 302.75 g mol "1 (267.30 g mol" 1);

3) mass fraction of pyronine Y cation: 80%, determined by absorption spectrometry;

4) permissible limits of interfering substances, given as mass fractions:

Water: less than 1%;

Inorganic salts: less than 0.1%;

Detergents: absent;

Colored impurities including violet crystals: not detectable by thin layer chromatography;

Indifferent compounds: 19% soluble starch;

c) wavelength of maximum absorption of the dye solution: 550 nm;

d) thin layer chromatography: there is only one major component, which coincides with pyronine Y;

e) Handling and storage: Stable when stored in a carefully closed brown glass bottle at room temperature between 18 ° C and 28 ° C.

A.2.4 Intended use of the Methyl Green-Pyronine Y staining method

A.2.4.1 Type (s) of material

Methyl green-pyronine Y dye is used for dyeing fresh frozen, waxed or plastic tissue sections different types.

A.2.4.2 Handling and handling before staining Possible fixing agents include:

Carnoy liquid [ethanol (volume fraction 99%) + chloroform + acetic acid (mass fraction 99%), mixed in volumes (60 + 30 + 10) ml] or

Formaldehyde (mass fraction 3.6%), phosphate-buffered (pH = 7.0); routine drying, cleaning, soaking and paraffin coating; routine preparation of sections using a microtome.

A.2.4.3 Working solution

A solution of ethyl green or methyl green is prepared from an amount corresponding to the weight of 0.15 g of pure dye, calculated as a colored cation (in the above examples, 0.176 g in each case) in 90 ml of hot (temperature 50 ° C) distilled water.

Dissolve the amount corresponding to the weight of 0.03 g of pyronine Y, calculated as a colored cation (in the example above 0.038 g) in 10 ml of 0.1 mol / l phthalate buffer (pH = 4.0). The latter solution is mixed with a solution of ethyl green or methyl green.

A.2.4.4 Stability

The working solution is stable for at least one week when stored in a tightly closed brown glass bottle at room temperature between 18 ° C and 28 ° C.

A.2.4.5 Staining procedure A.2.4.5.1 Dewax the sections.

A.2.4.5.2 Wet the sections.

A.2.4.5.3 Stain the sections for 5 min at room temperature about 22 ° C in a working

solution.

А.2.4.5.4 Wash the sections in two changes of distilled water, from 2 to 3 s each.

A.2.4.5.5 Shake off excess water.

A.2.4.5.6 Activate in three changes of 1-butanol.

A.2.4.5.7 Transfer directly from 1-butanol to a hydrophobic synthetic resin.

A.2.4.6 Expected result (s)

The following results are expected with the material types listed in A.2.4.1:

a) for nuclear chromatin: green (Karnov's fixative) or blue (formaldehyde fixative); a) for nucleoli and cytoplasm rich in ribosomes: red (Karnov's fixative) or lilac-red (formaldehyde fixative);

c) for cartilage matrix and mast cell granules: orange;

d) for muscles, collagen and erythrocytes: not stained.

A.3 Felgen-Schiff reaction

A.3.1 Coloring substance pararosanilin

CAUTION - For R 40: possible risk irreversible effects.

For S 36/37: Protective clothing and gloves are required.

The following information applies to the dye pararosanilin.

a) product identity:

1) pararosanilin (synonyms: basic ruby, parafuchsin, paramagenta, magenta 0);

2) CAS registration number: 569-61-9;

3) name and index number of paints: basic red 9, 42500;

b) composition:

1) the molecular formula, including the counterion: Ci9Hi 8 N 3 + SG;

2) molar mass with (and without) pritivion: 323.73 g mol "1 (288.28 g mol" 1);

3) mass fraction of pararosanilin cation: 85%, determined by absorption spectrometry;

4) permissible limits of interfering substances, given as mass fractions:

Water: less than 1%;

Inorganic salts: less than 0.1%;

Detergents: not present;

Colored impurities: methylated pararosanilin homologues may be present in trace amounts as determined by thin layer chromatography, but acridine is absent;

Indifferent compounds: 14% soluble starch;

c) wavelength of maximum absorption of the dye solution: 542 nm;

d) thin layer chromatography: one main component is present, corresponding

pararosaniline; methylated homologues of pararosanilin in trace amounts;

e) Handling and storage: Stable when stored in a carefully sealed brown bottle at room temperature between 18 ° C and 28 ° C.

A.3.2 Intended use of the Felgen-Schiff reaction

A.3.2.1 Type (s) of material

The Felgen-Schiff reaction is used for waxed or plastic sections of various types of tissues or cytological material (smear, tissue print, cell culture, monolayer):

A.3.2.2 Handling and handling prior to staining

A.3.2.2.1 Possible fixing agents

Possible fixing agents include:

a) histology: formaldehyde (mass fraction 3.6%), phosphate-buffered, (pH = 7.0);

b) cytology:

1) liquid fixing material: ethanol (volume fraction 96%);

2) air dried material:

Formaldehyde (mass fraction 3.6%), phosphate-buffered;

Methanol + formaldehyde (mass fraction 37%) + acetic acid (mass fraction 100%), mixed in volumes (85 + 10 + 5) ml.

The material fixed in Buin's fixative is unsuitable for this reaction.

Details of the method used by the manufacturer to study the reactivity of the chromogenic reagent are given in A.3.2.2.2-A.3.2.4.

A.3.2.2.2 Pararosanilin-Schiff reagent

Dissolve 0.5 g of pararosaniline chloride in 15 ml of 1 mol / l hydrochloric acid. Add 85 ml of an aqueous solution of K 2 S 2 0 5 (mass fraction 0.5%). Wait 24 hours. Shake 100 ml of this solution with 0.3 g of charcoal for 2 minutes and filter. Store the colorless liquid at a temperature not lower than 5 ° C. The solution is stable for at least 12 months in a tightly closed container.

A.3.2.2.3 Wash solution

Dissolve 0.5 g of K 2 S 2 O s in 85 ml of distilled water. Add 15 ml of 1 mol / l hydrochloric acid. The solution is ready for immediate use and can be used within 12 hours.

A.3.2.3 Staining procedure

A.3.2.3.1 Dewax the waxed sections in xylene for 5 min, then rinse for 2 min, first in ethanol with a volume fraction of 99% and then in ethanol with a volume fraction of 50%.

A3.2.3.2 Soak plastic sections, dewaxed wax sections and cytological material in distilled water for 2 min.

A.3.2.3.3 Hydrolyze the material in 5 mol / L hydrochloric acid at 22 ° C for 30 to 60 min (the exact hydrolysis time depends on the type of material).

A.3.2.3.4 Rinse with distilled water for 2 min.

A3.2.3.5 Stain with pararosanilin reagent for 1 h.

A3.2.3.6 Wash in three consecutive changes of washing solution, 5 min each.

A.3.2.3.7 Wash twice with distilled water, 5 min each time.

A.3.2.3.8 Dehydrate in 50% v / v ethanol, then 70% v / v and finally 99% ethanol for 3 min each time.

A.3.2.3.9 Wash twice in xylene for 5 min each time.

A.3.2.3.10 Extract into synthetic hydrophobic resin.

A.3.2.4 Expected results

The following results are expected with the types of materials listed in A.3.2.1:

For cell nuclei (DNA): red.

A.4 Immunochemical demonstration of estrogen receptors

CAUTION - Reagent containing sodium azide (15 mmol / L). NaN 3 can react with lead or copper to form explosive metal azides. When removing, wash off with plenty of water.

A.4.1 Monoclonal murine anti-human estrogen receptor

The following information pertains to the monoclonal murine anti-human estrogen receptor.

a) product identity: monoclonal mouse anti-human estrogen receptor, clone 1D5;

b) clone: 1D5;

c) immunogen: recombinant human estrogen receptor protein;

d) source of antibodies: monoclonal mouse antibody supplied in liquid form as tissue culture supernatant;

e) specificity: the antibody reacts with the L / -terminal domain (A / B region) of the receptor. When immunoblotted, it reacts with a 67 kDa polypeptide chain obtained by transformation of Escherichia coli and transfection of COS cells with plasmid vectors expressing the estrogen receptor. In addition, the antibody reacts with cytosolic extracts of the luteal endometrium and human breast cancer MCF-7 cells;

f) cross-reactivity: the antibody reacts with the rat estrogen receptors;

e) composition: tissue culture supernatant (RPMI 1640 medium containing fetal calf serum), dialyzed against 0.05 mmol / L Tris / HCI, pH = 7.2, containing 15 mmol / L No. N3.

Ig concentration: 245 mg / l;

Ig isotype: IgGI;

Light chain identity: kappa;

Total protein concentration: 14.9 g / l;

h) Handling and storage: Stable up to three years when stored at 2 ° C to 8 ° C.

A.4.2 Intended use

A.4.2.1 General

The antibody is used for the qualitative and semi-quantitative detection of estrogen receptor expression (eg, breast cancer).

A.4.2.2 Type (s) of material

The antibody can be applied to formalin-fixed paraffin sections, acetone-fixed frozen sections, and cell smears. In addition, the antibody can be used to detect antibodies by an enzyme-linked immunosorbent assay (ELISA).

A.4.2.3 Staining procedure for immunohistochemistry

A.4.2.3.1 General

For paraffinated formalin-fixed tissue sections, a variety of sensitive staining technologies are used, including immunoperoxidase, APAAP (alkaline phosphatase anti-alkaline phosphatase) technology, and avidin-biotin methods, such as LSAB (Labeled StreptAvidin-Biotin) methods. Antigen changes such as heating in 10 mmol / L citrate buffered saline, pH = 6.0, are required. Slides should not dry out during this treatment or during the next immunohistochemical staining procedure. The APAAP method was proposed for staining cell smears.

Details of the procedure used by the manufacturer on formalin-fixed waxed tissue sections to study antibody reactivity for immunohistochemistry are given in A.4.2.3.2 -A.4.2.3.4.

A.4.2.3.2 Reagents

А.4.2.3.2.1 Hydrogen peroxide, mass fraction 3% in distilled water.

A.4.2.3.2.2 Tris buffer saline (TBS), consisting of 0.05 mol / L Tris / HCI and 0.15 mol / L NaCl at pH =

A.4.2.3.2.3 Primary antibody, consisting of the monoclonal murine anti-human estrogen receptor, optimally diluted in TBS (see A.4.2.3.4).

A.4.2.3.2.4 Biotinylated goat anti-mouse / rabbit immunoglobulin antibody, working

Prepare this solution at least 30 minutes, but not earlier than 12 hours before use, as follows:

5 ml TBS, pH = 7.6;

50 μl biotinylated, affinity-isolated goat anti-mouse / rabbit immunoglobulins in 0.01 mol / l phosphate buffered saline, 15 mmol / l # N3, sufficient to bring the final concentration to 10-20 mg / ml.

A.4.2.3.2.5 StreptAvidin-biotin / horseradish peroxidase complex (StreptABComplex / HRP), working

Prepare this solution as follows:

5 ml TBS, pH = 7.6;

50 μl StreptAvidin (1 mg / L) in 0.01 mol / L phosphate buffer solution, 15 mmol / L NaN 3;

50 μl of biotinylated horseradish peroxidase (0.25 mg / l) in 0.01 mol / l phosphate buffer solution, 15 mmol / l NaN 3;

A.4.2.3.2.6 Diaminebenzidine substrate solution (DAB)

Dissolve 6 mg of 3,3 "-diamine benzidine tetrahydrochloride in 10 ml of 0.05 mol / l TBS, pH = 7.6. Add 0.1 ml of hydrogen peroxide 3% by weight in distilled water. If precipitation occurs, filter.

A.4.2.3.2.7 Hematoxylin

Dissolve 1 g of hematoxylin, 50 g of aluminum potassium sulfate, 0.1 g of sodium iodate and 1.0 g of citric acid in 750 ml of distilled water. Dilute to 1000 ml with distilled water.

where the coefficient k characterizes the capture rate, and the exponent m is the order of the reaction. The value of k varies from 0 to oo. In this case, at Kg - coefficient taking into account the quality of the base; I is the height of the free fall of coal, m.

where P is the angle of inclination of the reflecting surface, degree; W + 5 ~ - content of the class larger than 6 mm,%.

Both the nature of the impacts and external mechanical loads occurring at the drops in the traffic flow are determined by the design parameters of the transfer devices and means of transport: the height of the drop, the stiffness and angle of inclination of the reflecting surface, the speed and angle of inclination of the feeding conveyor and other factors.

at an angle and to the horizon from a height h to a reflecting surface, inclined in turn at an angle P. At the point of collision of the reflecting surface and anthracite, the speed of its fall can be decomposed into normal vn and tangent vr with respect to the reflecting surface components. The kinetic energy of collision is determined by the normal component Vn, which can be determined by the formula

The classifications in force today consider coal mainly as an energy fuel, therefore, they do not sufficiently reflect the properties important for the processes of chemical-technological processing. Currently, research is underway in many countries to develop methods for unambiguously assessing the suitability of any coal for different directions its technological use, including for processing into motor fuels. In the Soviet Union, in recent years, the development of such a unified classification has been completed: days of coals based on their genetic and technological parameters. According to this classification, the petrographic composition of coal is expressed by the content of fused microcomponents. The stage of metamorphism is determined by the vitrinite reflection indicator, and the degree of recovery is expressed by a complex indicator: for brown coals - by the yield of semi-coking tar, and for bituminous coals - by the yield of volatiles and sintering capacity. Each of the classification parameters reflects certain features of the material composition and molecular structure of coals.

Until 1989, each coal basin had its own classification, enshrined in the corresponding GOST. The basis of these classifications for dividing coals into grades and within each grade into groups were: the yield of volatile substances, the thickness of the plastic layer and the characteristics of the non-volatile residue when determining the yield of volatile substances. Since 1991, the Unified Classification of Bituminous Coals has been introduced. According to the standard, which provides for new classification parameters, coals are divided by types, depending on the value of the vitrinite reflection index, the heat of combustion and the release of volatile substances into brown, stone and anthracite.

Kevich and Yu.A. Zolotukhin tried to develop a method for predicting the strength of coke taking into account the petrographic composition and the reflection index of vitrinite. The heterogeneity of the coals in the charge was taken into account in terms of the degree of metamorphism and microlitotypic composition. The indicator of the thickness of the plastic layer was also taken into account, as well as the ash content of the predicted charge, calculated from the additivity.

As can be seen, within each pair of charge differentiated by batteries, there are no noticeable differences in ash content, total sulfur content, and sintering capacity. The yield of volatile substances is somewhat lower for the charges intended for coke oven battery No. 1-bis. The values of the complex indicators for all variants correspond to or are close to the optimal median values; in this case, some preference can still be given to the charges for battery No. 1-bis. Table 6 shows the characteristics of sintering, confirming this position. The petrographic characteristics of the experimental charges, including the average values of the vitrinite reflectance index and the distribution of various stages of metamorphism within the vitrinite component of coal charges, are presented in Table. 7.

Charge options Vitrinite reflection index р О / "0, / О Stage of vitrinite metamorphism,%

petrographic;

The stage of metamorphism is established by the reflectivity of vitrinite. The essence of the method is to measure and compare the electric currents arising in the photomultiplier tube under reflected light from the polished surfaces of the sample and the reference sample. The vitrinite reflectance index for bituminous coals ranges from 0.40 to 2.59.

Low-rank coals are coals with a gross calorific value of less than 24 MJ / kg and an average vitrinite reflectance /? „Less than 0.6%;

Coals of a higher rank are considered to be coals with a gross calorific value equal to or more than 24 MJ / kg, as well as with a gross calorific value of less than 24 MJ / kg, provided that the average reflectance of vitrinite is equal to or greater than 0, b%.

Average reflectance of vitrinite, K, "% - two digits

The first two digits of the code indicate the reflectivity of the vitrinite, corresponding to the lower limit of the 0.1% range of values of the average reflectance of vitrinite, multiplied by 10;

Measuring the reflectance of vitrinite Ro% is one of the most common methods for assessing the degree of maturation of organic matter in sediments. The reflectivity of vitrinite is measured as the ratio of the intensities of the reflected and incident light beams. According to the physical laws of reflection and refraction of light,

The fraction of intensity, Rо, of a ray of monochromatic light that is normally reflected from a flat surface of a piece of vitrinite with a refractive index n immersed in oil with a refractive index n o (or in air with an index n а) is equal to:

The refractive indices n and n o are determined by the integral temperature history of the vitrinite sample, i.e. function T (t). The method is based on the idea that during coalification vitrinite changes its reflectivity from Ro = 0.25% at the peat stage to Ro = 4.0% at the anthracite stage (Lopatin and Emets, 1987). The huge factual material accumulated to date makes it possible to identify certain stages of maturation based on the measured values of Ro%. In this case, variations are possible in the values of x Ro% for OF different types, as well as depending on the content of impurities in the OM. So, Ro = 0.50% approximately corresponds to the beginning of the main stage of oil formation for high-sulfur kerogens, while Ro = 0.55 - 0.60% - the same stage for kerogens of types I and II (see below), and Ro = 0.65 - 0.70% - for type III kerogens (Gibbons et al., 1983; Waples 1985). One of the options for the supposed correspondence of Ro% values to the main stages of OM maturation and the calculated values of the temperature-time index (TWI) discussed below can be seen in Table 1-7a as well as on rice. 1-7... The correspondence of the stages of catagenesis to the Ro values given in the table is based on the correlation between the calculated Temperature-Time Indices (TWI) and the Ro% values measured in different basins of the world, and is approximate. However, it is widely used in the literature and is discussed in more detail in section 7-5-1. For the convenience of orientation in various scales of OM catagenesis, Tables 1-7b also show the scale of correspondence of values

Table 1-7a. Correspondence of Ro% and TVI values to the stages of OM catagenesis(Waples, 1985)

the reflectance of vitrinite% Ro to the OM maturity stages adopted in Russian petroleum geology.

Table 1-7b. Correspondence of Ro% values to the stages of OM catagenesis accepted in Russian petroleum geology(Parparova et al., 1981)

Diagenesis: DG3, DG2 and DG1 ------ Ro< 0.25%

Protocatagenesis: PC1 (0.25 £ Ro £ 0.30%)

PK2 ((0.30 £ Ro £ 0.42%)

PK2 ((0.42 £ Ro £ 0.53%)

Mesocatagenesis: MK1 (0.53 £ Ro £ 0.65%)

MK2 ((0.65 £ Ro £ 0.85%)

MK3 ((0.85 £ Ro £ 1.15%)

MK4 ((1.15 £ Ro £ 1.55%)

MK5 ((1.55 £ Ro £ 2.05%)

Apocatagenesis: AK1 (2.05 £ Ro £ 2.50%)

AK2 ((2.50 £ Ro £ 3.50%)

AK3 ((3.50 £ Ro £ 5.00%)

AK4 ((Ro> 5.00%)

Let us briefly describe some of the problems associated with the use of% Ro measurements to assess the degree of OM catagenesis. They are primarily associated with the difficulty of separating vitrinite macerals from OM of sedimentary rocks due to their great diversity. The use of the reflectivity of vitrinite to control paleotemperature conditions is possible, generally speaking, only on the basis of vitrinite from coal beds and, with less reliability, vitrinite from the continental (“terrestrial”) parent OM in clays with an organic carbon content not exceeding 0.5%. However, caution should be exercised in these terrestrial series, as in rocks such as sandstones, the bulk of the OM can be recycled and altered (Durand et al. 1986). It is also necessary to take into account the fact that in any case for Ro> 2% the reflectivity will also depend on the pressure. Care should also be taken in extending the concept of vitrinite to marine and lacustrine rock series, since in such rocks, the particles whose reflectivity is measured are rarely vitrinite of higher plants and in most cases

Rice. 1-7. Correlation of vitrinite reflectivity, Ro%, and degree of coalification with other maturity indices and with the position of zones of generation and decomposition of oil and gas. Top: after (Kalkreuth and Mc Mechan, 1984), bottom after (Tissot et al., 1987).

are bituminoids from plankton, mistaken for vitrinite (Waples, 1985; Durand et al. 1986). In terms of thermophysical properties, they differ from vitrinite. A similar problem exists for terrestrial Cambrian-Ordovician and older rocks. They cannot contain vitrinite, since higher plants did not exist then. OM is oxidized in all red-colored formations. In limestones, vitrinites are less frequently preserved and, if present, their reflectivity may differ from the values for normal vitrinite of the same degree of coalification (Buntebarth and Stegena, 1986).

Certain errors in this method for assessing OM catagenesis will also arise due to significant scatter in the measured values of Ro, as well as due to the fact that the basin section will always contain horizons in which the separation of vitrinite is difficult or impossible at all. For example, at low maturity levels, the isolation of vitrinite macerals is a big problem, and therefore the reliability of Ro measurements for values less than 0.3–0.4% is extremely low (Waples et al. 1992). The dependence of the reflectivity of vitrinite on the initial chemical composition of vitrinite will be significant (Durand et al. 1986). This explains the fact that a large spread in Ro% values is often observed even within the same basin (Tissot et al. 1987). To make an error from variations in the chemical composition of vitrinite, the minimum Ro% measurement is carried out on samples of regular vitrinite, isolated by standard procedure from organic matter of continental origin. It is not recommended to use equivalent types of vitrinite in OM types I and II when creating universal scales of correspondence of Ro% values to the degrees of OM conversion (Tissot et al. 1987).

And yet, with reasonable consideration of the comments made, the method for assessing the level of OM maturity and controlling through it the paleotemperature conditions of subsidence of the sedimentary strata based on measurements of the reflectivity of vitrinite is currently one of the most reliable and widespread methods in the practice of analyzing oil and gas basins.

7.3 Using% Ro and Other Methods to Estimate Maximum Rock Temperatures in Basin Submersion History

Initially, reflectivity measurements of vitrinite were used to estimate the maximum temperatures Tmax in the submersion history of the suite. For similar purposes, a number of methods have been and are being applied in geological studies, such as (Yalcin et al., 1997): 1) estimates of T max by the level of OM maturity (degree of coalification, vitrinite reflectance; 2) estimates based on mineralogical changes during diagenesis of clay minerals and crystallization of illite; 3) methods based on the analysis of liquid inclusions, for example, the temperature of liquid homonization; 4) geothermometers based on specific chemical reactions, for example, characterizing the equilibrium of stable isotopes (Hoefs, 1987) or the equilibrium states of the SiO 2 -Na-K-Ca system (Ellis and Mahon, 1977); 5) Fizzion-track analysis (analysis of the distribution of traces from the fission of radioactive elements in appatite; Green et al., 1989; 1995); 6) based on a combination of determination of the radiometric age of such radiometric systems as K-Ar, Rb-Sr and U, which are closed when different temperatures(Buntebarch and Stegena, 1986). Since paleotemperature estimates are still widespread in the geological literature, we briefly describe each of these methods. Let us begin our presentation with estimates of the maximum temperatures of rocks based on the values of the reflectance of vitrinite.

It should be noted right away that the development of methods for assessing the maximum temperatures in the history of subsidence of sedimentary formations (T max) is due to the fact that in the 70s and 80s of the last century, many researchers considered temperature as the main and, in fact, the only factor in the evolution of sedimentary OM maturity. In this case, the influence of time on the process of OM maturation was neglected. It was believed that the measured (or calculated) values of the reflectance of vitrinite% Rо should reflect the maximum temperatures of the rocks in the history of their immersion. Following these views, various correlations have been proposed between the T max values and the reflectance of the vitrinite rock in air% R a and in oil% Ro. For example, in the works of Ammosov et al. (1980) and Kurchikov (1992), it is proposed to estimate the values of T max from the measured values of% R a from the ratio

10 × R а (%) = 67.2 × (7-1)

For samples of carbonaceous interlayers in rocks, from the ratio

10 × R а (%) = 67.2 × (7-2)

For sandstones and siltstones and according to the equation

10 × R а (%) = 67.2 × (7-3)

For clays and mudstones. In the above expressions, T max is expressed in ° C. Price (1983) also believed that a time of one and even more million years does not have a noticeable effect on the OM maturation process and, on this basis, proposed a relation similar to (7-1) - (7-3), linking T max with a reflectivity of vitrinite in oil (% Ro):

T max (° С) = 302.97 × log 10 Ro (%) + 187.33 (7-4)

Several similar relationships have been considered by K. Barker (Barker and Pawlevicz, 1986; Barker, 1988, 1993). The first is (Barker and Pawlevicz, 1986):

ln Ro (%) = 0.0078 × T max (° С) - 1.2 (5)

based on 600 T max measurements in 35 wells in different basins of the world. According to the authors, it is valid in the temperature range 25 £ T max £ 325 ° C and the reflectivity of vitrinite 0.2% £ Ro £ 4.0%. K. Barker (Barker, 1988) proposed a relationship describing situations with a constant heating rate of rocks during submersion in a basin:

T max (° С) = 104 × ln Ro (%) + 148. (7-6),

and based on a kinetic model of vitrinite maturation (Burnham and Sweeney, 1989). M. Johnson et al. (Johnsson et al., 1993), analyzing this formula, note that it describes well the situation with heating rates V = 0.1 - 1 ° C / million. years, but for velocities V = 10 - 100 ° C / mln. years underestimates the values of T max in the Ro region< 0.5% и переоценивает их при Ro >2%. In his later work, Barker (1993) proposed another version of the correlation between T max and% Ro, which does not contain restrictions on the heating rate of rocks:

T max (° С) = [ln (Ro (%) / 0.356)] / 0.00753 (7-7)

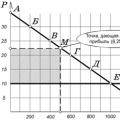

Thus, in the literature, quite a lot of correlation relations T max -% Ro are proposed. On rice. 2-7 they are compared with each other according to the results of T max estimates for values of 0.4% £ Ro £ 4.0%.

Rice. 2-7. Relationships linking the maximum temperature T max in the history of subsidence of the rock with the measured values of the reflectance of vitrinite in oil% Ro, according to various literary sources: 1 (for coals), 2 (for sandstones and siltstones), 3 (for clays and mudstones) - ( Ammosov et al., 1980; Kurchikov, 1992); 4 - (Price, 1983); 5 - (Barker and Pawlevicz, 1986); 6 - (Barker and Pawlevicz, 1986); 7 - (Barker, 1993); 8 - according to the temperature of homogenization of liquid inclusions (Tobin and Claxton, 2000).

This figure shows a significant scatter in the T max values corresponding to fixed Ro values, which reaches 60 - 100 ° С for the maturity Ro ³ 0.7%. This scatter unambiguously indicates that the temperature value (even the maximum one) alone cannot determine the maturity of OM in rocks, and that the temperature holding time plays a significant role in the maturation of OM. It is possible that in some intervals of Ro and under special conditions of sedimentation (such as those that ensure a constant rate of heating of rocks) some of the above ratios describe the situation well, but as studies show (see below), the same% Ro values can be achieved, for example, at lower temperatures but with longer rock holding times (see below). For this reason, there is always a basin and formation with an appropriate maturity and temperature range, for which estimates based on ratios (7-1) - (7-7) will lead to noticeable errors. This circumstance led to the fact that the popularity of the written out ratios has noticeably decreased over the past 10-15 years.

Another common method for assessing the paleotemperatures of rocks in basins is the determination of T max by analyzing the composition of fluids captured by the matrix of rocks during diagenesis. The method can be applied if the following conditions are met (Burruss 1989): 1) the inclusion is a single-phase liquid, 2) the volume of this liquid does not change after it is captured by the rock, 3) its composition also remained unchanged, 4) the effect of pressure on the composition of the liquid is known in advance, 5 ) the time and mechanism for trapping the liquid are also known. These conditions suggest that some caution is needed in the application of the method (Burruss 1989). First, detailed petrographic studies are required to establish the relative time of formation of the fluid inclusion. Second, a thorough analysis of the tectonic development of the area and the history of the basin subsidence is required to detail the history of the host rocks. An analysis of the phase behavior and chemical composition of the trapped liquid is also required. But even after that, two important problems remain - one associated with the assumption of the invariability of the chemical composition of the liquid after it has been captured by the rock matrix (there is convincing evidence that this is not always the case), and the other, associated with the determination of the magnitude and type of pressure that existed during the period fluid storage - whether lithostatic or hydrostatic (Burruss 1989). If all these problems are solved, the temperature of the rock at the moment of entrapment of the liquid is determined by the corresponding P-T diagram of the equilibrium of the liquid and solid phases of the investigated substance. In the development of this method, Tobin and Claxton (2000) proposed to use the correlation between the homogenization temperature of liquid inclusions T hom and the reflectance of vitrinite Ro% (Fig. 2-7):

Ro% = 1.9532 ´ log T hom - 2.9428 (7-8)

They found that when using an “ideal” series of measurements, relation (7-8) is satisfied with a correlation coefficient of 0.973 and a data variance of less than 0.12% Ro. If the entire range of world data is used, then the ratio is of the form:

Ro = 2.1113 ´ log T hom - 3.2640 (7-9)

will be performed with a correlation coefficient of 0.81 and a maximum data variance of less than 0.32% Ro (Tobin and Claxton, 2000). The homogenization temperature T hom is often used as an estimate of the maximum rock temperature T max during its immersion in the basin. However, fig. 2-7 shows that the curve constructed according to the formula (7-9) differs markedly from the estimates of T max according to the formulas (7-1) - (7-7), crossing the rest of the lines in Fig. 2-7. She clearly lowers the temperatures for Ro< 1.5% и даёт нереально высокие значения при Ro >2% (Th = 540, 930, and 1600 ° C for Ro = 2.5, 3, and 3.5%, respectively).

Figure 3-7 Change in d 13 C isotope ratio with depth for a gas field in the Anadarko Basin (USA; Price, 1995).

In a number of works (Rooney et al., 1995; Price, 1995, etc.), to estimate the temperature of hydrocarbon generation, it is proposed to use the change in the isotopic composition of carbon in the course of OM catagenesis (Figure 3-7)... Results of experiments on the generation of gases of OM type II (parent rocks of the Delaware and Val Verde basins in western Texas) at a constant heating rate of 1 ° C / min (left rice. 4-7; Rooney et al., 1995) demonstrate a noticeable change in the isotopic composition of gases

Rice. 4-7. Gas generation temperature and d 13 C isotopic ratio for methane (d 13 C 1), ethane (d 13 C 2), and propane (d 13 C 3) generated by type II kerogen from the Delaware and Val Verde basins in western Texas at heating rate of rocks 1 ° С / min (left figure, according to Rooney et al., 1995) and isotopic ratio d 13 C for methane generated at different temperatures during hydroid pyrolysis of rock samples with different types of organic matter (right figure, after Price, 1995).

with temperature and thus confirm the fundamental possibility of using this dependence to estimate the generation temperature of gases of this type of OM. The same is indicated by the results of hydroid pyrolysis of rock samples with different types of organic matter, shown in the left figure. 4-7. They also clearly demonstrate the change in the isotopic ratio d 13 C for methane generated at different temperatures (Price, 1995). However, these experiments also indicate an extremely high sensitivity of changes in d 13 C to variations in the composition and type of OM, due to which the application of the method is possible only after a detailed analysis of the composition of OM and obtaining the corresponding dependences specifically for the type of substance being analyzed. A wide scatter in the values of d 13 C with depth, shown in Fig. 3-7 for a typical section of a sedimentary basin is mainly caused by variations in the composition and type of organic matter in the rocks of the macro and micro layers of the section. This scatter greatly limits the reliability of the temperature estimates based on isotope ratios in gases of real sedimentary sections.

The process of converting smectite to illite in clay minerals is also sometimes used to control paleotemperature conditions in basins. But, rice. 5-7 shows that the temperature ranges typical for the process are rather wide. This variation in temperature is not surprising, as laboratory studies show that the conversion of smectite to illite is driven by a 6th order kinetic reaction (Pytte and Reynolds, 1989) and, therefore, time affects the rates of these transitions along with temperature. These reactions will be considered in more detail in the final section of this chapter, but here we note that reasonable estimates of the temperature of the transition of smectite to illite are possible only for the isothermal version of the transformation of minerals, but even then the error of the method will be noticeable.

Figure 5-7 Conversion of clay minerals based on analysis of samples from 10 wells in the North Sea (Dypvik, 1983). The processes of disappearance of smectite and illite layers of different levels in mixed-layer smectite-illite clay minerals are tied to the values of temperatures and reflectivity of vitrinite.

Of all the microcomponents of organic matter, vitrinite is the best from the point of view of indicativeness in the study of the degree of catagenetic transformation. The fact is that, for reliable diagnostics, a microcomponent is needed, which must have a regular change in properties during the transformation process, at the same time it must be widespread in OM. Vitrinite meets all the above requirements, in contrast to other microcomponents of coals and DOM. Which either merge with the total organic mass of coals already at the middle stages of catagenesis (leupinite), or weakly and unevenly react to changes in environmental parameters (fusinite). And only vitrinite changes its properties naturally gradually and is very easy to diagnose.

It is on the basis of the reflectivity of vitrinite that most of the scales for determining the degree of catagenesis are built. In addition to it, other microcomponents of DOM are used, but to a lesser extent. The method is based on the regularity of the increase in brightness in the process of catagenesis. This can be easily seen visually if we consider the change in the luster of the coals in the process of their change. No special instruments are required to notice that the luster of anthracite, for example, is much higher than that of brown coal. Reflectivity is closely related to the internal structure of a substance, namely the degree of packing of particles in a substance. It just depends on it. Of course, the study of the degree of catagenesis in terms of reflectivity is carried out using special equipment, for example, the installation of a POS-I device consists of a polarizing microscope, an optical attachment, a photomultiplier tube (PMT) and a recording device. The study compares the photocurrents caused by the light reflected from the surface of the sample and the reference.

So, vitrinite, or rather its reflectivity, was taken as a standard during research. It is measured using various photometers and standards in air and immersion medium at strictly perpendicular incidence of light on a well-polished sample surface. Measurements are carried out only in a narrow wavelength range: from 525 to 552 nm. This limitation is due to the technical characteristics of the device. A wavelength of 546.1 nm is taken as the standard, but small fluctuations around this value have practically no noticeable effect on the measurement value. The sample is fixed on the microscope stage and stopped so that its surface is perpendicular to the axis of the optical attachment. As mentioned above, we measure the intensity of the reflected light alternately from the sample and the reference using a photomultiplier. By definition, reflectivity is the ability to reflect some of the light incident on a surface. If you translate this into numerical language, then this is the ratio of reflected light to incident light.

What can be written as:

Where I1 is the intensity of the reflected light and I2 is the intensity of the incident light. In practice, when making measurements, the formula is used

Here R is the desired reflectance, d is the instrument readings when measuring the test substance, and R1, respectively, is the standard reflectance and d1 is the instrument readings when the standard is measured. If you tune the receiving device to zero for the reference, then the formula is simplified to R = d.

In addition to vitrinite, other OM microcomponents are also used for measurements. Some of them have the property of reflectivity anisotropy. Three measurement parameters are commonly used: Rmax Rmin Rcp. An increase in vitrinite anisotropy during catagenesis is mainly associated with the process of gradual ordering of aromatic humic micelles associated with an increase in pressure with increasing immersion depth. Measurements in the case of an anisotropic sample are no different conceptually from the measurement of a homogeneous sample, but several measurements are taken. In this case, the microscope stage rotates 360? at intervals of 90 ?. Two positions with the highest reflectance and two with the lowest reflectance are always detected. The angle between each of them is 180 °. Measurements are taken for several pieces of rock and the average is calculated later. As the arithmetic mean of the mean of the maximum and minimum measurement:

You can immediately determine the average by choosing a rotation angle of 45? from the maximum or minimum value, but this measurement is correct only when studying a weakly converted OM.

When doing research, several technology-related problems arise. For example, if we have a rock with a low total organic matter content, then there is a need for special processing of the sample and its conversion into the form of concentrated polished sections-briquettes. But in the process of obtaining concentrates, the original organic substance undergoes chemical treatment, which cannot but affect the optical properties of the substance. In addition, information about the structure of the organic matter of the rock is lost. Measurements can be distorted by the fact that the technology of the preparation process is not standardized and the readiness of the sample is usually determined visually. The problem is also physical properties rocks, such as strong mineralization or brittleness of coal, in this case it is necessary to study the reflectivity on the surface area that was obtained. If you choose the right site, then the surrounding defects practically do not affect the measurements. But the principally quantitative values of errors practically do not affect the determination of the stage of catagenesis.

Samples are studied, usually under normal air conditions, it is easy and fast. But if a detailed study is required under a high magnification, immersion media are used, usually cedar oil. Both measurements are correct and each of them is used, but each in its own specific case. The advantages of measurements in an immersion medium are that they allow the study of particles with a small dimension, in addition, the sharpness is increased, which makes it possible to diagnose the degree of catagenesis in more detail.

An additional difficulty in research is the diagnosis of the microcomponents of OM, since they are usually detected in transmitted light. While the reflectivity is obviously reflected. That's why. Usually, in the research process, two methods are combined. That is, transmitted and reflected light is used alternately to study the same fragment of DOM. For this, double-sided polished sections are usually used. In them, after viewing and determining the microcomponent in transmitted light, the illumination is switched and measurements are taken in reflected light.

Vitrinite can be used not only to determine the degree of transformation of organic matter, but also to determine its relationship to the rock. In syngenetic vitrinite, the shape of the fragments is usually elongated, the particles are located parallel to the bedding planes, and usually have a cellular structure. If we are dealing with vitrinite particles of a rounded, rounded shape, then most likely this is a redeposited substance.

05 01 medical biochemistry where to work

05 01 medical biochemistry where to work Biochemistry who can work

Biochemistry who can work Types of monopolies: natural, artificial, open, closed

Types of monopolies: natural, artificial, open, closed