Greenhouse business plan. How to start a greenhouse business? Greenhouse frame as a business

In the Russian climate, greenhouses and hotbeds are often the only reliable way to get a good harvest. There are several ways to produce and install greenhouses - it all depends on your financial capabilities and plans.

Climate change in recent decades has forced the search for unconventional ways to grow vegetables and fruits. Growing crops outdoors has become more problematic due to deteriorating ecology, unstable weather conditions, the often uncontrolled use of chemicals, etc.

Using greenhouses for growing crops was a way out. In addition, in the Russian climate, the greenhouse allows you to harvest much earlier, and often get harvests all year round, than significantly increase the profit of the business owner. Greenhouses are easily located in cottage and summer cottages, in summer health institutions, farms and even on the territory of industrial enterprises.

The production of greenhouses has become a promising business for the reasons listed above. Let's consider what it takes to organize this profitable and promising business.

Details of the business idea for the production of greenhouses

Consider several options for the "greenhouse" business. The meaning of such a business is the production and subsequent installation of greenhouses and greenhouses. A promising option for the development of such a business may be the production of winter gardens and greenhouses. They differ from greenhouses in the complexity of their design, the use of new materials and a much higher cost. However, the demand for such structures is constant, especially with good advertising and the reputation of the manufacturer.

Greenhouses can be built from scratch using special equipment purchased or rented. You can also purchase individual elements from manufacturers (supports, fences, stairs, doors, etc.) to complement their own designs.

There are three groups of greenhouses:

- individual;

- farm;

- industrial.

The differences between them are in area, level of equipment, process automation and, of course, in cost.

It is possible to manufacture greenhouses of the following types:

- with a frame made of polyethylene pipes and a film cover;

- with a frame made of wood and frames with foil or glass;

- with a metal frame and wooden frames;

- completely metal with glass.

Ordinary glass is not used for the manufacture of greenhouses, since it does not transmit ultraviolet light, which is necessary for plant growth. You need to use special glass or plastic wrap.

Option 1

Specialized enterprises produce greenhouses of various sizes, ranging from the smallest with an area of 12 sq. m and 24 sq. m. The cost of such greenhouses starts at 20,000 rubles. An interesting type of business can be the installation of greenhouses on site. It is easy to transport the greenhouse: the frame weighs 50-90 kg and can be transported in the trunk of a car. The cost of installing such greenhouses is about 10-20 thousand rubles.

Option 2

Greenhouses are usually made independently from polycarbonate, pipes and plastic wrap. The easiest way is to make arch-type greenhouses, structurally consisting of arcs attached to the soil surface without a foundation. A transparent film of different density (depending on the customer's request) is stretched over the arcs.

Installation of such a structure is very simple, the cost of materials is also low. To start a business for this reason, the production and installation of arched greenhouses is unlikely to be justified. Additional costs there will also be drawings, frame structures and coating materials. A small greenhouse will cost at least 8,000 rubles.

Option 3

Novice businessmen can be recommended to start with the production of polycarbonate greenhouses-pavilions. These are tall structures, designed to accommodate a person in full height... Polycarbonate is durable (service life 30-35 years), with good thermal insulation. On a pre-prepared frame made of galvanized iron sheet is attached cellular polycarbonate... The sheets are connected together with a factory sealed tape. For the installation of such greenhouses, it is often required to concrete the foundation. And this is an additional well-paid job.

The production costs of such a greenhouse are low - only about 10,000 rubles. The whole complex of works lasting 2 days with the cost of the greenhouse will cost the client about 25,000 rubles.

An additional advantage of such a greenhouse is the absence of complex structures that must be ordered separately. The client should be attracted by an individual approach to his order. A greenhouse or greenhouse of the required size will be made and installed exactly where it is needed. This is especially important for complex areas, where it is often necessary to install greenhouses near permanent buildings.

The specifics of the greenhouse business

To start work on the production and installation of greenhouses does not require large funds. If a production site with equipment for the production of greenhouse structures is not provided, then 70-80 thousand rubles is quite enough. The invested funds can be recouped very quickly if you have permanent orders.

Industrial equipment for the production of structural elements of greenhouses can be purchased gradually as the business develops. The customer base is the main thing in this business. It should be borne in mind that the need for greenhouses is seasonal. Advertising should be constantly present in specialized publications for gardeners, farmers, etc. Submit information about yourself in horticultural associations, dacha communities. Place ads in rural district newspapers, on radio, TV.

Maximum demand for greenhouses in spring and autumn. In winter, it will be necessary to "switch" to winter gardens and greenhouses. Working with such structures is more difficult, so you can start it after gaining some experience with greenhouses. It is better to start a greenhouse business in February, before the start of the season. Thus, the invested funds can be quickly returned and invested in business development.

It is becoming more and more popular. But in order to succeed in this business, it is important not only to know the technology of their manufacture. The choice of equipment for the production of greenhouses is not the least important.

General information

Nowadays, people tend to eat ecologically clean products... Most have their own summer cottages and grow vegetables and fruits themselves. But they cannot do without certain equipment. Entrepreneurship in the field of providing such people with everything they need is gradually gaining momentum.

Country greenhouses are especially popular. They differ from each other in size, equipment and configuration. For their manufacture, use various materials... By design, greenhouses are divided into personal, industrial and farm greenhouses.

Plastic constructions

Polycarbonate greenhouses are considered the most common type, which is in great demand. This material is a great alternative to film and glass. Such greenhouses have a lot of advantages:

- The quality of the material that ensures their long service life (about 30 years or more).

- Light conducts well.

- Protects from UV radiation.

- Good thermal insulation.

- Manufacturing materials are inexpensive.

Polycarbonate is a practical material that is lightweight, flexible and durable. Structures from it are obtained stable.

Equipment for the production of polycarbonate greenhouses

The technology is as follows:

- a frame is made (shaped pipe 20 * 20, 25 * 25, etc.);

- using the factory tape, you need to connect the plastic sheets and fix them to the structure.

The tools used in the manufacture are as follows:

- welding machine;

- screwdriver;

- compressor with spray gun;

Parts are made in a utility room, for example, in a garage. It should be large enough to accommodate a greenhouse machine (cutting and processing plastic, for example). And the installation is carried out already at the place where the client says. This usually happens in the garden. A foundation is made on the greenhouse in advance and then it is installed. Although you can do without it. At the end, they put windows and doors.

Is it cost effective?

The cost price of a greenhouse is 10 thousand rubles, provided that it is made independently. All work takes about 4 hours. For a day of labor, after deduction of expenses, you can get on initial stage about 30 thousand rubles. All stages of the greenhouse installation process take 2 days.

The cost of installation is no more than 25 thousand rubles. The greenhouse can be installed without a foundation. In this case, the buyer saves a significant amount. In addition, less time is spent on installation. The costs will also be for heating (aluminum convectors that are installed around the entire perimeter of the greenhouse).

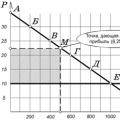

The profitability of this project is 100-150%. But there is one important circumstance: the supply exceeds the demand. As mentioned above, polycarbonate greenhouses are popular. Therefore, there is plenty of competition in the market.

Other types of structures

And yet, do not despair, because there are still a lot of options in this direction. Some of them are more expensive, but they also cost more. The demand for them is also great. There are the following types of greenhouses:

- the frame is made of wood, the frames are glazed;

- metal frame using wooden frames;

- metal structure covered with glass (easily transmits ultraviolet rays);

- frame made of polyethylene tubes, film covering.

Selection of equipment for the production of greenhouses

You can purchase the necessary equipment in order to independently manufacture parts of a modular structure (tubes, supports, fences, etc.). The choice of equipment for the production of greenhouses depends on your Money... Its cost starts from 200 thousand rubles. Wood structures are usually handcrafted and expensive. If you do not have the required amount of money, then the component parts can be purchased from other entrepreneurs. Modular structures can be bought on average for 20-25 thousand rubles.

To start this kind of activity, you will need an amount of 60 thousand rubles - and this is without taking into account your own equipment. If you quickly build up a client base for yourself, then in a couple of months these investments will be able to pay off. In the absence of groundwork in this area, it is better for you to advertise in advance, bypass farmers and gardeners and talk to them.

It is possible that they will agree to cooperate with you. The production of greenhouses is in demand mainly in the spring-autumn period. The best months to start a business are February and March. You can continue to invest the earned money in your business. For example, in the choice of equipment for the production of greenhouses of greater capacity. In winter, you can do the conservatories and greenhouses. But such a business is more costly and complex than the production and installation of conventional greenhouses. The help of specialists in this matter will not be superfluous.

Every second owner of a private house or summer cottage has a positive attitude towards the possibility of installing a greenhouse in his subsidiary farm for growing cucumbers, tomatoes, cabbage, strawberries and even flowers. However, few have enough experience or resources to independently design and build such a structure.

Given this circumstance, the production of polycarbonate greenhouses is a highly profitable type of business that can be opened even in your own garage: the popularity of this type of greenhouse structures is mainly due to the affordable price and high performance characteristics of the materials used for their manufacture.

Business features

Entrepreneurs considering the manufacture and sale of polycarbonate greenhouses as promising business, in this type of activity, first of all, the low capital intensity of production and the high liquidity of the equipment used are attracted: it is enough to invest 170-200 thousand rubles in the purchase of ordinary power tools and find suitable suppliers of fairly common building materials.

Greenhouse demand peaks in early spring and late autumn. Therefore, it is best to start implementing this at the end of February in order to build up a client base of sufficient size by the beginning of the season. As for the cold season, greenhouses and various winter gardens are in demand at this time. Due to the structural complexity, the cost of such structures is several times higher than the price of standard greenhouses, however, their construction requires certain experience and skills: this is where the knowledge accumulated in the summer will come in handy.

It is also advisable to study how to build a thermos greenhouse for winter cultivation with your own hands: such designs are in demand among farmers and entrepreneurs who are engaged in floriculture or the cultivation of crops such as green onions, dill, parsley and strawberries throughout the year.

Business is distinguished by a profitability of 100-120%, but that is why it is quite difficult to find a free market niche: in large cities, supply significantly exceeds demand. The way out can be either the formation of competitive advantages that are interesting to the consumer (price promotions, warranty support, short order execution time), or an even narrower specialization - for example, the production of industrial greenhouses. In addition, when developing a marketing strategy, you must always remember who is target audience business:

- Owners of summer cottages and subsidiary farms who are interested in vegetable growing in order to meet their own needs;

- Farmers for whom the sale of greenhouse products is the main or additional way to generate income;

- Industrial greenhouse complexes with an area of dozens of hectares.

Types and purpose of greenhouses

Regardless of who becomes the buyer of such a greenhouse of its own production, the basic requirements for its design will be approximately the same - durability, strength, adaptability to regional climatic conditions, ease of use and low price.In addition, when choosing a model, everyone is guided by their own motives. The owner of the site, on which the landscape designer has worked thoroughly, will rather be interested in a stylish appearance and the original architectural solution, while the entrepreneur considering, first of all, will pay attention to the operational characteristics and the possibility of adapting the interior space to specific production needs.

To a certain extent, preferences are also influenced by the list of plant species that are supposed to be cultivated in artificial conditions: for example, for planting tomatoes, or you need a rectangular structure with vertical walls, because in the first case, the bushes are high and grow poorly under arched vaults, and in the second, flower pots are placed in several tiers.

In addition to the classification by purpose (seedling, vegetable and flower), greenhouse structures are also divided according to the form into:

- Rectangular with a gable roof. The greenhouse frame outwardly resembles a house with walls up to 1.5 m high and a ridge located at a level of 1.8–2.2 m. Thanks to this shape, the owner does not have to bend his head while working, and the vertical arrangement of the walls allows plants to be placed on racks and shelves. Another advantage of the design is a large roof slope: when manufacturing polycarbonate greenhouses, the calculated value of the snow load can be reduced, since the snow will slide down under the influence of gravity;

- Arched. In this case, the greenhouse frame is based on arcs with a radius of 2–2.2 m located in a row. Due to the absence of corners and planes, the structure is characterized by a minimum consumption of covering material, good light transmission and high resistance to wind loads, however, snow from horizontal sections of the roof has to be removed manually. In addition, special equipment is required for the manufacture of arched greenhouses, and therefore it is rather difficult to build such a structure from scrap materials;

- Rectangular with sloping walls. The shape of such a greenhouse is an intermediate option that combines the advantages of an arched and a gable structure. Due to the fact that the walls are installed with a slope, the usable area of the base increases, and the amount of reflected sunlight decreases;

- Wall mounted. With a good location of the capital structure (house, shed), a greenhouse with a pitched roof can be attached directly to its wall: this option allows you to save on building materials and use the area of the site as efficiently as possible. In addition, in some cases, the entrance is equipped directly from the room, turning the structure into a greenhouse;

- Polygonal. Octahedral buildings with a hipped roof are constructed mainly for decorative purposes, using metal and glass (less often monolithic polycarbonate) as a material for the manufacture of a greenhouse. Nevertheless, the design is not devoid of practical advantages: at different times of the day, each facet is illuminated by direct sunlight.

Polycarbonate greenhouse production technology

Do-it-yourself step-by-step production of a greenhouse is technologically uncomplicated process accessible to anyone with minimal power tool experience. The installation of a standard design in this case includes the following steps:

- Arrangement of the foundation. Construction Materials and the type is chosen based on the requirements and financial capabilities of the customer;

- Frame fabrication. On special equipment for the manufacture of greenhouses, the main elements are cut. For wood processing, circular and band saws are used, for cutting and bending a profile pipe - metal-cutting and rolling machines;

- Assembly of the structure. On the prepared foundation, a frame is assembled, which is subsequently sheathed with polycarbonate sheets;

- Installation of additional elements. Greenhouse construction work is completed with the installation of doors, manual or automatic vents, heating and irrigation systems, shelving, as well as the arrangement of beds.

Foundation

The construction of the foundation, including the greenhouse, requires preliminary marking and leveling of the surface of the site. Then, in accordance with the nature of the soil, a specific structure is selected - tape, block, brick or wood. It should be noted that the cost of manufacturing a polycarbonate greenhouse directly depends on the option chosen: a strip foundation is considered the most expensive and durable, and one made from a bar at a low cost requires replacement every 5-6 years. However, each species is characterized by its own advantages and disadvantages:- Wooden from a bar 100x100 mm. In addition to the low price, the main advantages of this type include low weight, accessibility and mobility: if necessary, the structure can be disassembled and moved to a new place. However, despite the antiseptic impregnation, the tree becomes unusable after a few years in conditions of high humidity with constant contact with the ground;

- Blocky. Before installing such a foundation, you need to dig a trench around the perimeter of the greenhouse, and then place concrete blocks in it and align them in a horizontal plane. The high cost of the structure in this case is due to the laboriousness of construction and the need to use lifting equipment for the production of polycarbonate greenhouses, which is fully compensated by the service life measured by decades;

- Brick or stone. To lay natural stone or bricks, you must either own the skill of a bricklayer, or be able to attract qualified specialists to the construction. In terms of cost, such a foundation is the most expensive, and in terms of service life it practically does not differ from a block foundation;

- Tape. A complex and expensive foundation - for its construction, you need to dig a trench, install the formwork, strap the reinforcement and pour concrete. Accordingly, making a polycarbonate greenhouse with your own hands requires the inclusion in the list of equipment of a concrete mixer, a welding machine, shovels and wheelbarrows for transporting land. Despite the high cost, this solution is one of the most popular due to its reliability, durability and the ability to get a perfectly flat base.

Frame

When making a polycarbonate greenhouse with your own hands, to assemble the frame, you can use any materials that have sufficient strength - rolled metal, wooden beams, gypsum plasterboard profiles and even polypropylene pipes. However, despite the lightness and cheapness, the last two options in mass production are quite rare - the domestic buyer prefers more solid structures:

- Wooden frame. In addition to low thermal conductivity, this option is characterized by ease of installation and ease of processing of elements - to make a wooden greenhouse, it is enough to have a hacksaw and a screwdriver at your disposal. All elements are assembled on corners and screws, and then treated with antiseptics or drying oil. Significant disadvantages of a wooden frame are the high price and fragility;

- Steel frame. The basis of this design is rolled metal - a corner, a channel, a square or rectangular pipe. For the manufacture of a greenhouse from a profile pipe, it is advisable to use galvanized elements, since at high humidity, even annual repainting does not save the metal from corrosion. The main advantages of the steel frame are durability and practicality, and the disadvantages include increased thermal conductivity, the presence of temperature deformations (which is especially important in the manufacture of large industrial greenhouses) and the laboriousness of installation: mainly welding or bolted joints are used for assembly.

Coating

Due to its low thermal conductivity, high strength and reasonable price, cellular polycarbonate is the optimal material for making a greenhouse. This thermoplastic with a thickness of 3.5 to 10 mm is produced in sheets 2.1 m wide and 6 or 12 meters long: it is advisable to take these dimensions into account when designing the structure in order to avoid waste.

The only drawback of the material is high thermal deformation, reaching 5 mm per meter of length (taking into account the difference between winter and summer temperatures). Therefore, for fastening the sheets, special joints are used that allow some mobility of the polycarbonate relative to the frame:

- Plastic thermal washers. The large diameter (33 mm) and the presence of an elastic sealing ring allows such a fastener to securely hold the sheet even in strong winds, and the cap provided by the design protects the screw head from corrosion;

- Detachable or one-piece H-profile. In this case, the profile itself is attached to the frame, and the sheets are inserted into its side grooves and held there by frictional force. This technology for the production of greenhouses requires an accurate calculation of thermal gaps in order to avoid falling out of polycarbonate from the profile in winter and "swelling" in summer;

- Galvanized tape. The sheets are overlapped on the frame and pressed at regular intervals with a taut steel tape. It should be noted that this mounting method can only be used in arched structures.

Polycarbonate has an open honeycomb, into which not only dust and dirt, but also various insects can easily fall. To protect the ends of the sheets, all joints are glued with a plastic perforated tape, and the lower edges are additionally protected with U-shaped end caps.

Premises

As a business, the production of greenhouses on a wooden or metal frame does not require a large room: final assembly design and cutting of sheets are carried out exclusively at the customer's site. Fulfill one-time orders it is even possible in your own garage, if you install a machine here for the production of polycarbonate greenhouses, however, with an increase in the scale of the enterprise, there is inevitably a need for a territory for storing raw materials and finished products. Therefore, at a certain stage of business development, you will have to search for a workshop that meets the following requirements:

- Total area - from 40 m², including storage facilities;

- Ceilings 3.5–4 m high up to overlap;

- Connection to 220/380 V power grids;

- Availability of heating for winter operation.

In large regional centers, such production areas can be rented in industrial zones at a rate of 200–250 rubles / m² per month.

Equipment

The organization of business in the production and sale of polycarbonate greenhouses involves the purchase of not only power tools, but also specialized equipment designed to work with rolled metal. For example, making an arched-type greenhouse with your own hands from a profile pipe requires a special pipe bending machine: depending on financial capabilities, you can choose a low-performance model with a manual drive, or a more powerful version with an electric one.

A concrete mixer, shovels and wheelbarrows for the ground are used in the construction of strip and block foundations, and the welding machine is used when assembling the frame and tying fittings. To save on transport services, it is desirable for an entrepreneur to also have at his disposal a car for transporting equipment, frame parts and polycarbonate sheets.

Equipment list

| Name | price, rub. |

| LBM (Bulgarian) | 2500 |

| Greenhouse Roll Forming Machine | 56000 |

| Pendulum cutting machine | 21000 |

| Concrete mixer 200 l | 13000 |

| Welding machine | 7000 |

| Cordless screwdriver | 3500 |

| Aluminum ladder | 2500 |

| Drill | 4000 |

| Jigsaw | 3500 |

| Measuring and marking tool | 4000 |

| Consumables, drills, abrasive discs | 2000 |

| Hand tool | 5000 |

| Total: | 124000 |

Financial investments and profit

When calculating the volume of initial investments, an entrepreneur needs to take into account not only the costs of purchasing equipment for the production of greenhouses, but also the costs of conducting an active advertising campaign... Developing your own website can also be a good way to attract customers: buyers often study the prices and characteristics of products from different manufacturers on the Internet.

Initial investment

The amount of current monthly expenses is determined mainly by the size wages staff. Of course, at the initial stage, you can independently start making greenhouses with your own hands, however, as the flow of customers increases, you will have to additionally hire two assemblers to assemble products, and one master to work in the workshop.

Current monthly expenses

To calculate the profit from the manufacture and installation of polycarbonate greenhouses to order or for sale, you need to draw up a detailed estimate, including the cost of purchasing material and fasteners, as well as the cost of all related work.

Estimates for the manufacture of a greenhouse 3x6x2.2 m

| Name | Qty | price, rub. | Amount, rub. |

| Galvanized profile 20x20x2 mm | 98 m | 102 | 9996 |

| Polycarbonate 2.1x6 m | 4 things. | 1650 | 6600 |

| Connecting profile | 12 m | 50 | 600 |

| End cap | 12 m | 42 | 504 |

| Perforated tape | 26 m | 16 | 416 |

| Roofing self-tapping screw 5.5x25 mm | 300 pcs. | 1,2 | 360 |

| Thermal washer polycarbonate | 300 pcs. | 5,7 | 1710 |

| Hinges | 8 pcs. | 20 | 160 |

| Total: | 20346 | ||

| Foundation | |||

| Tape | 18 m | — | 8000 |

| Blocky | 18 m | — | 5300 |

| From a bar 100x100 mm | 18 m | — | 1200 |

| Price on strip foundations: | 28346 | ||

| Price on a block foundation: | 25646 | ||

| Price on a foundation made of timber: | 21546 | ||

The market value of such a product without a foundation is at least 25,000 rubles, and the profit from its sale is 4,654 rubles. It should be noted that with large production volumes, the price of a greenhouse can be further reduced by receiving a wholesale discount on the purchase of a profile, polycarbonate and hardware.

Construction works

With a continuous flow of customers, four people (including the owner of the enterprise) can manufacture and install up to 15 arched greenhouses within a month. Income in this case is determined not only by the size of the product itself, but also by the type of foundation.

Income depending on the type of foundation

Advertising campaign

Related Videos

To quickly and reliably recoup the initial investment, you need to start working customer base even before searching for premises and purchasing equipment. If preliminary market research reveals the presence of significant demand and the absence of major competitors in the region, the list of equipment can be adjusted and, for example, more powerful machines can be purchased. In general, to find the first buyers, they use:

Almost all owners of country houses dream of their own greenhouse. Do-it-yourself vegetables are of low price and high quality. Entrepreneurs who decide to start growing tomatoes, cucumbers or strawberries cannot do without a good greenhouse. Therefore, such products are very popular among those who have relied on Agriculture and decided to grow vegetables and fruits. Greenhouse production as a business is profitable. To verify this, you should familiarize yourself with its main features.

Features of greenhouses

On modern market presented wide range of products made from different materials.

By designation, it is divided into:

- Industrial;

- Farmer's;

- Amateur.

In addition, they differ in design features and dimensions.

Start the production of industrial greenhouses with the choice of material. The most in great demand use polycarbonate construction. This material does not break, so it will last for a long time. In addition, polycarbonate allows only useful light to pass through, preventing the sun's rays from damaging the plants. These products are distinguished by their affordable price and high quality.

Equipment for the production of

If you want to run own production greenhouses, you need to purchase factory equipment. It costs more than 200 thousand rubles. For the manufacture of structures on a wooden base, you need to hire workers. In this case, the cost of production will increase significantly, but the demand for them remains consistently high.

Equipment for a greenhouse profile will cost 690 thousand rubles. This machine is designed for the production of steel profiles. It is equipped with a system automatic control... This allows you to program the location of the required mounting holes. With the help of a roller stand, a radius deflection is given to the profile. It is used for the production of arched products.

Schematic: greenhouse production

Types of greenhouses

According to the form of the structure, there can be:

- Gable;

- Single-pitched;

- Arched.

Depending on the material, they are divided into the following types:

- Glass. Such designs are in little demand, since glass is an expensive, fragile and too heavy material. So that it does not crack, it is necessary to equip a solid foundation;

- Film. Polyethylene film has been used for the production of greenhouses for a long time. The main advantages of such products are quick warm-up and the absence of a solid foundation. This material protects against frost up to -2 degrees;

- Polycarbonate. This material is the most popular. In terms of its heat-retaining characteristics, it can be compared to double glazing.

Expenses

The manufacture of one unit of production will have to spend 25 thousand rubles. If you will assemble a structure from ready-made elements without using own equipment, the cost of one will be 60 thousand rubles.

To organize a full-fledged production, you need to have start-up capital 1 million rubles. Of these, 700 thousand rubles is equipment for the production of greenhouses, and the remaining 300 thousand rubles is the purchase of materials.

To return the initial investment in 1 year, it is necessary to find sales markets, as well as offer customers services for the installation of greenhouses.

Home production

To make a greenhouse with your own hands, you do not need expensive equipment.

To get started, you need to purchase:

- Manual pipe bending machine - 15 thousand rubles;

- Cut-off pendulum machine - 35 thousand rubles;

- Welding machine - 9 thousand rubles.

The frame is made of galvanized iron. It can be purchased on the market or at a metal warehouse. Polycarbonate plates are fastened to the frame with a special tape. If you are interested in making a greenhouse with your own hands, a video on this topic can be found on the Internet.

With the appropriate skills, you can make 2-3 designs in a week, after the sale of which, you will recoup your initial costs. After that, you can expand your business and purchase a machine for the production of greenhouses. Thanks to this, you will be able to increase labor productivity and, accordingly, your income.

Business prospects and weaknesses

Despite the fact that the profitability of this business is 100–150%, not every entrepreneur can take his place in it. The reason for this is too high competition, as is the case with. In regions where this business is widespread, supply usually exceeds demand. To transport finished products to other regions is unprofitable, since it significantly increases the cost of products, and sell at high price not so easy.

DIY greenhouse assembly DIY greenhouse assembly

But if you are interested in the production of greenhouses as a business, you should not give up this venture. To stay afloat, you need to constantly expand the range and make customers profitable offer... For example, less reliable designs can be sold at a low cost. In addition, some entrepreneurs, in order to reduce the cost of production and attract new customers, make the frame not from metal, but from polyethylene tubes.

Some aspiring businessmen who do not have enough funds to start offer their services for installing greenhouses. They buy ready-made elements from large manufacturers. To open such a business, it is enough to have on hand only 60 thousand rubles. The most important thing is constant orders. Try looking for clients in holiday villages and horticultural associations.

Summing up

Since the production of greenhouses from polycarbonate and other materials is a seasonal business. These products are needed in spring and sometimes in autumn. Especially high demand observed in February - March. It is advisable to open a business during this period in order to invest the resulting profit in the development of your business. Before starting work, draw up a competent business plan for the production of greenhouses and try to strictly adhere to all its points.

To prevent production from idle in winter, glazed verandas, greenhouses or winter gardens can be produced. In addition, you can offer customers original wood products. self made, and . Their manufacture takes a lot of time, but such a design is very expensive. To develop your business, you need to look for different ways. Only then can you increase your fortune.

05 01 medical biochemistry where to work

05 01 medical biochemistry where to work Biochemistry who can work

Biochemistry who can work Types of monopolies: natural, artificial, open, closed

Types of monopolies: natural, artificial, open, closed