Basics of MRP-MRPII class systems. Manufacturing resource planning (MRP II) Mrpii is used as a business process management system

Philosophy and basic concepts of MRP In the early 60s, in connection with the growing popularity of computing systems, the idea arose to use their capabilities for planning the activities of an enterprise, including for planning production processes. The need for planning is due to the fact that the bulk of delays in the production process are associated with delays in the receipt of individual components, as a result of which, as a rule, in parallel with a decrease in production efficiency, there is an excess of materials in warehouses that arrived on time or earlier than planned. In addition, due to the imbalance in the supply of components, additional complications arise when taking into account and tracking their condition in the production process, i.e. it was virtually impossible to determine, for example, to which batch a given constituent element belongs in an already assembled finished product. In order to prevent such problems, the MRP (Material Requirements Planning) methodology was developed. The implementation of a system working according to this methodology is a computer program that allows you to optimally regulate the supply of components to the production process, controlling stocks in the warehouse and the production technology itself. The main task of MRP is to ensure the availability of the required amount of required component materials at any time during the planning period, along with possible reduction permanent stocks, and hence the unloading of the warehouse. Before describing the structure of the MRP itself, a short glossary of its main concepts should be introduced:

- Materials we will call all raw materials and individual components that make up the final product. In the future, we will not make a distinction between the concepts of "material" and "component".

- MRP system , MRP program- a computer program working according to an algorithm regulated by the MRP methodology. Like any computer program, it processes data files (input elements) and forms result files on their basis.

- Material status is the main pointer to the current state of the material. Each individual material, at each point in time, has a status within the MRP system, which determines whether this material is available in the warehouse, whether it is reserved for other purposes, whether it is present in current orders, or an order for it is only planned. Thus, the status of a material uniquely describes the degree of readiness of each material to be released into the production process.

- Safety stock material is necessary to support the production process in the event of unforeseen and unrecoverable delays in its supply. In fact, in the ideal case, if the supply mechanism is considered to be impeccable, the MRP methodology does not postulate the mandatory presence of a safety stock, and its volumes are set different for each specific case, depending on the current situation with the receipt of materials. More about this will be discussed below.

- Material requirement in the computer MRP program, it is a certain quantitative unit that reflects the need to order this material that has arisen at a certain point in time during the planning period. A distinction is made between the concept of a total requirement for a material, which reflects the quantity that needs to be put into production, and a net requirement, in the calculation of which the presence of all insurance and reserved stocks of a given material is taken into account. An order is automatically created in the system when a non-zero net requirement occurs.

- A guarantee of the availability of the required components and a decrease in time delays in their delivery, and, therefore, an increase in the production of finished products without an increase in the number of jobs and loads on production equipment.

- Reduction of manufacturing defects in the process of assembling finished products arising from the use of incorrect components.

- Sequencing of production, due to the control of the status of each material, which makes it possible to unambiguously track its entire conveyor path, from the creation of an order for a given material, to its position in an already assembled finished product. Also, thanks to this, complete reliability and efficiency are achieved. production accounting.

Formation of input information for the MRP program and the results of its work In practice, an MRP system is a computer program that can logically be represented using the following diagram:

Diagram 1 Input elements and results of the MRP program The above diagram shows the main information elements of an MRP system. So, let's describe the main input elements of an MRP system:

- Inventory Status File is the main input element of the MRP program. It should reflect the most complete information about all materials-components necessary for the production of the final product. This element must indicate the status of each material, which determines whether it is on hand, in stock, in current orders, or its order is only planned, as well as descriptions, its stocks, location, price, possible delivery delays, and supplier details. Information on all of the above items should be laid down separately for each material involved in the production process.

- Production program (Master Production Schedule) is an optimized time schedule for the production of the required batch of finished products for a planned period or a range of periods. First, a trial production program is created, and subsequently tested for feasibility, additionally by running through the CRP system (Capacity Requirements Planning), which determines whether there is enough production capacity for its implementation. If the production program is recognized as feasible, then it is automatically formed into the main one and becomes an input element of the MRP system. This is necessary because the scope of requirements for production resources is transparent to the MRP system, which forms a schedule for the occurrence of requirements for materials based on the production program. However, if a number of materials are unavailable, or it is impossible to fulfill the order plan necessary to maintain the production program implemented in terms of CPR, the MRP system, in turn, indicates the need to make adjustments to it.

- Bills of Material File is a list of materials and their quantity required to manufacture the final product. Thus, each final product has its own list of ingredients. In addition, it contains a description of the structure of the final product, i.e. it contains complete information on the technology of its assembly. It is extremely important to maintain the accuracy of all records in this element and adjust them accordingly whenever changes are made to the structure and / or production technology of the final product.

- Planned Order Schedule determines how much of each material should be ordered in each considered time period during the planning period. The order plan is a guide for further work with suppliers and, in particular, determines the production program for the internal production of components, if any.

- Changes in planned orders are modifications to previously planned orders. A number of orders can be canceled, changed or delayed, as well as postponed to another period.

- Exception report is intended to inform the user in advance of periods of time during the scheduling period that require special attention and in which external management intervention may be necessary. Typical examples of situations that should be reflected in this report may be unexpectedly late orders for parts, excess parts in warehouses, etc.

- Performance Report is the main indicator of the correct operation of the MRP system and is intended to notify the user about critical situations in the planning process, such as, for example, the complete depletion of safety stocks for individual components, as well as all system errors that occur during the operation of the MRP program.

- Planning Report is information used to make forecasts about possible future changes in the volume and characteristics of manufactured products, obtained as a result of analysis of the current progress of the production process and sales reports. Also, the forecast report can be used to long-term planning requirements for materials.

Production capacity planning using CRP-system (Capacity Requirements Planning) The CRP capacity planning system is used to test a pilot production program, created in accordance with forecasts of demand for products, for the possibility of its implementation with the available production facilities. During the operation of the CRP system, a plan for the distribution of production capacities is developed for processing each specific production cycle during the planned period. Also installed technological plan sequences production procedures and, in accordance with the trial production program, the utilization rate of each production unit for the planning period is determined. If, after the cycle of the CRP-module, the production program is recognized as really feasible, then it is automatically confirmed and becomes the main one for the MRP-system. Otherwise, it is modified and retested using the CRP module. In the further evolutionary development of production planning systems, they began to represent the integration of many separate modules, which, interacting, increased the flexibility of the system as a whole. In the next section, the main stages of the further development of systems of the MRP class will be described.

Evolution of MRP. Moving from MRP to MRPII

Manufacturing planning systems are constantly evolving. Initially, MRP systems actually simply formed an order plan for a certain period based on the approved production program, which did not fully satisfy the growing needs.

In an effort to increase scheduling efficiency, in the late 1970s, Oliver White and George Plosle proposed the idea of a closed loop in MRP systems. The idea was to propose to consider a wider range of factors in planning, by introducing additional functions. It was proposed to add a number of additional functions to the basic functions of planning production capacities and planning material requirements, such as monitoring the conformity of the quantity of products produced to the quantity of components used in the assembly process, drawing up regular reports on order delays, on the volume and dynamics of product sales, on suppliers, etc. etc. The term "closed cycle" reflects the main feature of the modified system, which consists in the fact that the reports created during its operation are analyzed and taken into account at further planning stages, changing, if necessary, the production program, and therefore the order plan. In other words, additional functions provide feedback in the system that provides planning flexibility in relation to external factors, such as the level of demand, the state of affairs at suppliers, etc.

Subsequently, the improvement of the system led to the transformation of the closed-loop MRP system into an extended modification, which was later called MRPII (Manufactory Resource Planning), due to the identity of the abbreviations. This system was created for the effective planning of all resources of a manufacturing enterprise, including financial and personnel. In addition, the MRRPII class system is able to adapt to changes in the external situation and emulate the answer to the "What if" question. MRPII is the integration of a large number of individual modules such as business process planning, material requirements planning, capacity planning, financial planning, investment management, etc. The results of the work of each module are analyzed by the entire system as a whole, which, in fact, provides its flexibility in relation to external factors. This property is the cornerstone modern systems planning, since a large number of manufacturers produce products with a deliberately short life cycle, requiring regular revisions. In this case, there is a need for an automated system that allows you to optimize the volumes and characteristics of products, analyzing the current demand and the situation in the market as a whole.

In recent years, planning systems of the MRPII class in integration with the financial planning module FRP (Finance Requirements Planning) were called ERP (Enterprise Requirements Planning) business planning systems, which allow the most efficient planning of all commercial activities modern enterprise, including financial expenses for equipment renovation projects and investments in the production of a new product line. In Russian practice, the feasibility of using systems of this class is determined, in addition, by the need to manage business processes in conditions of inflation, as well as severe tax pressure, therefore, ERP systems are necessary not only for large enterprises, and for small firms running an active business. The following diagram shows the logical diagram of a manufacturing plant resource planning system:

Diagram 2. The logical structure of the resource planning system of a manufacturing enterprise.

MRP systems simply form a plan of orders for a certain period, which became insufficient with the increasing needs of management.

The disadvantages of MRP systems began to manifest themselves more and more in connection with the constantly growing competition in the market, the vital need for companies to constantly restructure production to meet the changing requirements of the consumer, life cycle products. All this required a revision of views on production planning and all activities of the company. Marketing began to manage production planning. All this led to the birth of the MRPII concept - a new concept of corporate planning.

Evolution of MRP -systems took place in the following way.

MRPsimply informs about the lead time of purchase orders, helping to plan the settlement of accounts with suppliers.

MRP / CRPadditionally provides information on the number of key production personnel, the level of hourly tariff rates and time norms for performing technological operations (in the description of technological routes), possible overtime work, etc., allowing you to plan production capacity.

MRPIIplans the needs of the entire production in materials, production facilities, finances, warehouses etc., based on the production plan.

1. Planning of production facilities using CRP-system (Capacity Requirements Planning)

The first expansion of the range of tasks was (almost simultaneously with MRP) methodology CRP (Capacity Requirements Planning) - the purpose of which is to check the feasibility of the main schedule in terms of the available equipment and, if it is feasible, to optimize the utilization of production capacities.

During the operation of the CRP system, a plan for the distribution of production capacities is developed for processing each specific production cycle during the planned period. Also, a technological plan for the sequence of production procedures is established and, in accordance with the trial production program, the degree of utilization of each production unit for the planning period is determined.

If, after the cycle of the CRP-module, the program is not recognized as really feasible, then changes are made to it, and it is re-tested using the CRP-module.

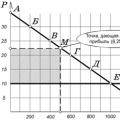

The CRP algorithm can be roughly divided into two stages: preliminary and final planning:

RCCP (Rough-Cut Capacity Planning)

Preliminary planning of production facilities. The procedure is enough quick check several key resources, with which you can find out if there is enough capacity to fulfill the main production plan.

FCRP (Finite Capacity Resource Planning)

Final planning of production facilities. Even though the RCCP may indicate that there is sufficient capacity to meet the production plan, FCRP may show a capacity shortfall in certain periods time.

For the CRP mechanism to work, the results of the work are required MPR -systems and three arrays of initial data.

Production schedule data, (They are also source for MRP).

Data on work centers, a description of the structure of production work centers with an indication of their capacity; Typically, the production facilities of an enterprise are classified into work centers. Such a production unit can be a machine tool, a tool, a worker, etc.

Data on technological routes manufacturing of nomenclature items. All information about the procedure for carrying out technological operations and their characteristics ( technological times, staff, other information). This dataset, together with the first dataset, forms the work center load.

CRP informs about all discrepancies between the planned load and the available capacity allowing the necessary regulatory actions to be taken. In this case, each manufactured product is assigned a corresponding technological route with a description of the resources required for each of its operations, at each work center.

In the course of the CRP module, a plan for the distribution of production capacities for the manufacture of each specific product is developed. In accordance with the trial production program, the degree of utilization of each production piece of equipment in the planned time period is determined. If, after the CRP module is running, the production program is recognized as executable, then it becomes the main one for the MRP module. Otherwise, it is modified and re-evaluated using the CRP module.

CRP does not do load optimization , carrying out only calculation functions according to a predetermined production program, simulates a given production system.

2. ClosedcycleMRP (Closed loop MRP)

In the late 70s, Oliver White and George Plosle ( Oliver Wight, George Plossl ) proposed the idea of Closed Loop MRP in MRP systems. The idea was to propose to consider a wider range of factors in planning: control of the conformity of the quantity of manufactured products to the quantity of components used in the assembly process, preparation of regular reports on delays in orders, on the volume and dynamics of sales of products, on suppliers, etc. with the implementation of feedback in the system, providing planning flexibility in relation to external factors. This idea came next after MRP / CRP along the path of standard development MRP.

The main idea behind this improvement in MRP technology is creating a closed loop by creating feedbacks that improve tracking of the current state production system... The additional implementation of monitoring the fulfillment of the supply plan and production operations made it possible to remove those limitations on the degree of reliability of the planning result, previously inherent in MRP I, which existed due to the inability to track the status of open orders.

APICS(American Production and Inventory Control Society) gives the following definition of the "Closed Loop MRP" methodology:

"A system built around material requirements planning (MRP), which includes additional scheduling functions such as production planning (aggregate planning), master production scheduling, and Capacity requirements planning Once the planning phases described above have been passed and the plans have been accepted as realistic and achievable, plans are executed, which includes production management functions such as input / output material flow (input) measurement. output (capacity) measurement), detailed scheduling and scheduling, as well as reporting on anticipated plant and supplier scheduling, supplier scheduling, etc. The term “closed loop” means that these elements are not simply included in common system but there is also feedback from the execution functions so that planning is always correct. " .

Usually involves two-phase planning and management, consisting of a "planning phase" and an "execution phase". The first involves the actual implementation of the MRP II methodology, which ends with the approval of plans, the second phase includes the functions of fulfilling plans - that is, the procurement of the necessary materials and components, the implementation of production targets, and the shipment of products to the consumer. The term "close loop" implies not only that both phases are part of a common system, but also that there is feedback between the execution functions and the planning functions, so that planning can be kept up to date at all times. However, in reality, the "classic" MRP II products support exactly two-phase operation, since frequent recalculation of plans is a significant problem and is really feasible only on a periodic basis (for example, not more than once a day, preferably less often).

3. Manufacturing resource planning (MRP II)

Further expansion functionality material requirements planning systems - MRP, led to the creation of production resource planning systems - MRP II (Manufacturing Resource Planning). Z Note the abbreviation “ MRP "Has changed, just as its meaning has actually changed!This is, in fact, an automated planning system for all resources of a manufacturing enterprise, including planning in natural units, financial planning in value terms, personnel, as well as elements of modeling production situations.

A fully functional MRP II system should contain 16 of the following software modules:

The MRP II class software product, according to the standards approved by APICS (American Production and Inventory Control Society), includes the following 16 functions:

- Sales and production planning ( Sales and Operation Planning);

- Demand management ( Demand Management);

- Drawing up the main production plan ( Master Production Scheduling);

- Material Requirements Planning ( Material Requirements Planning);

- Product specifications ( Bill of materials);

- Warehouse management (Inventory Transaction Subsystem);

- Supply planning (Scheduled Receipts Subsystem);

- Management at the production floor level ( Shop Flow Control);

- Capacity planning ( Capacity Requirement Planning);

- Input / output control ( Input / Output Control);

- Purchases ( Purchasing);

- Scheduling allocation resources (Distribution Resourse Planning);

- Planning and control of production operations ( Tooling Planning and Control);

- Financial planning ( Financial Planning);

- Modeling ( Simulation);

- Performance assessment ( Performance Measurement).

It is extremely important to pay attention to the feedback functions in the MRPII system. For example, if suppliers are unable to deliver parts within the agreed time frame, they should send a delay report as soon as they become aware of the problem. Typically, a standard company has a large number of overdue orders with suppliers. But, as a rule, the dates of these orders do not sufficiently reflect the dates of the actual demand for these materials. In enterprises controlled by systems of the MRPII class, the delivery dates are as close as possible to the time of the actual demand for the supplied materials.

Therefore, it is extremely important to inform the system in advance about possible problems with orders. In this case, the system must generate a new production capacity plan in accordance with the new order plan. In a number of cases, when the delay in orders is far from an exception, the volume is set in the MRPII system.

MRP system as a whole:

Description of plan items and planning levels;

Description of planning specifications;

Formation of the main production plan of the schedule.

MRP subsystem:

Product management (description of materials, components and units of finished products);

Inventory Management;

Product configuration management (product composition);

Maintaining a bill of materials;

Calculation of the requirements for materials;

Formation of MRP purchase orders;

Formation of MRP transfer orders.

CRP subsystem:

Work centers (description of the structure of production work centers with the definition of capacity);

Machines and mechanisms (description of production equipment with the definition of standard capacity);

Manufacturing operations performed in relation to work centers and equipment;

Technological routes, representing a sequence of operations performed over time on a specific equipment in a specific work center;

Calculation of capacity requirements to determine the critical load and make a decision.

19. Systems of class MRPII. Differences from MRP, structure of MRPII system, advantages of using MRPII systems.

However, the MRP concept has a serious flaw. The fact is that when calculating within the framework of this concept, the need for materials does not take into account either the available production capacity, nor their load, nor the cost of labor. This flaw was corrected in the concept of MRPII (Manufacturing Resource Planning). MRPII made it possible to take into account and plan all production resources of an enterprise - raw materials, materials, equipment, personnel, etc.

As the concept of MRPII developed, the ability to account for the rest of the enterprise's costs was gradually added to it. This is how the concept of ERP (Enterprise Resource Planning), sometimes also called enterprise resource planning, appeared.

The MRPII system should consist of the following functional modules (Figure 3.):

Business development planning module defines the mission of the company: its niche in the market, assessment and determination of profits, financial resources. In fact, he states, in conventional financial units, what the company is going to produce and sell, and estimates how much money needs to be invested in product development and development in order to reach the planned profit level. Thus, the output element of this module is a business plan.

Sales planning module evaluates (usually in units of a finished product) what the volume and dynamics of sales must be in order to fulfill the established business plan. Changes to the sales plan will undoubtedly lead to changes in the results of other modules.

Production planning module approves the production plan for all types of finished products and their characteristics. Each type of product within the product line has its own production program. Thus, the totality of production programs for all types of manufactured products represents the production plan of the enterprise as a whole.

Material requirements planning module(or types of services) on the basis of the production program for each type of finished product determines the required schedule for the purchase and / or internal production of all materials of the components of this product, and, accordingly, their assembly.

Production capacity planning module converts the production plan into the final units of the load of working capacities (machines, workers, laboratories, etc.)

Feedback module allows you to discuss and solve emerging problems with suppliers of components, dealers and partners. Thus, this module actually implements the famous "closed loop principle" in the system. Feedback is especially necessary when changing individual plans that turned out to be impossible and subject to revision.

Figure 3. - Interaction of modules in the MRPII system

Class systemMRP(Material Requirements Planning)- a system working according to the algorithm regulated by the MRP methodology, which allows to optimally regulate the supply of components to, controlling the stocks in the warehouse and the production technology itself.

MRP class system Based on planning the material needs of a department of an enterprise, an organization as a whole.

The main task of MRP is to ensure that the required quantity of required component materials is available at any time during the planning period, along with the possible reduction of permanent stocks, and, therefore, unloading of the warehouse.

Purposes of using the MPR standard:- planning the supply of all components in order to eliminate production downtime and minimize stocks in the warehouse;

- reduction of stocks of component materials, except for the obvious unloading of warehouses;

- Reducing storage costs provides a number of undeniable advantages, the main one of which is minimization of the frozen funds invested in the purchase of materials.

- Description of the state of materials (Inventory Status File) - is the main input element of the MRP-module. It should reflect the most complete information about all types of raw materials and component materials necessary for the production of the final product. Also must be indicated (the status of each material, which determines whether it is on hand, in a warehouse, in current orders or its order is only planned, as well as descriptions, its stocks, location, prices, possible delivery delays, supplier details;

- Production program (Master Production Schedule) - an optimized time distribution schedule for the production of the required batch of finished products for a planned period or a range of periods;

- Bills of Material File - a list of materials and their quantity required to manufacture the final product. It also contains a description of the structure of the final product.

- For each period of time, a complete demand for materials is created. It is an integrated table expressing the need for each material at any given time.

- The net need is calculated(how many materials need to be ordered (or produced, in the case of internal production of components) at any given time

- The net material requirement is converted into the corresponding order plan for the required materials and, if necessary, the existing plans are amended.

- Planned Order Schedule - how much of each material should be ordered in each considered time period during the planning period.

- Changes in planned orders - modifications to previously planned orders .

There is a serious flaw in the MRP concept. When calculating the requirements for materials, the following are not taken into account:

- labor cost, etc.

Therefore, in the 80s. The closed loop MRP system has been transformed into manufactory resource planning system), which was named MRPII... It is a system for joint planning of stocks and production resources, characterized by:

- business planning;

- sales planning;

- production planning;

- planning material needs;

- planning of production facilities;

- various control systems.

The MRPII standard was developed in the USA and is maintained by the American Production and Inventory Control Society (APICS).

Requirements for systems of class MRPII - must fulfill a certain scope of these basic functions:- Planning of sales and production (Sales and Operation Planning).

- Demand Management.

- Drawing up a production plan (Master Production Scheduling).

- Material Requirements Planning(Material Requirements Planning).

- Bill of Materials.

- Warehouse management(Inventory Transaction Subsystem).

- Scheduled Receipts Subsystem.

- Shop Flow Control.

- Production capacity planning(Capacity Requirement Planning).

- Input / output control.

- Material and technical supply (Purchasing).

- Resource allocation planning(Distribution Recourse Planning).

- Planning and control of production operations (Tooling Planning and Control).

- Financial management(Financial Planning).

- Simulation

- Performance Measurement.

The essence of the MRPII concept : forecasting, planning and production control is carried out throughout everything, from the purchase of raw materials to the shipment of products to the consumer.

As a result of using MRPII systems, the following should be implemented:- prompt receipt of information about the current results of activities both in general and with full details for individual orders, types of resources, implementation of plans;

- long-term, operational and detailed planning of the enterprise's activities with the possibility of adjusting planned data based on operational information;

- optimization of production and material flows with a significant reduction in non-production costs and a real reduction in material resources in warehouses;

- reflection of the financial activities of the enterprise as a whole.

- Galaxy 7.1

- SunSystems

- Concorde XAL

- Platinum

- Microsoft Dynamics

- Scala

- orientation only to order,

- poor integration of design and engineering,

- poor integration of the system of technological processes,

- poor integration of personnel planning and financial management.

Main idea MRP systems, the main elements of MRP, MRP II (Manufactory Resource Planning), the logic of the MRP II-system, focused on assembly (discrete) production. Development of MRP II: extension to "non-discrete" types of production. Features of the implementation of MRP-II systems

1.MRP (Material Requirements Planning)

In the 60s, through the efforts of the Americans Joseph Orlicky and Oliver Weight, a method for calculating the materials required for production was created, called MRP (Material Requirements Planning). Thanks to the dedicated work of the American Association for Inventory and Production Management (APICS), the MRP method has become widespread throughout the Western world, and in some countries (including Russia) it is even interpreted as a standard, although it is not.

In what cases is the use of MRP systems appropriate?

First of all, it should be noted that MRP systems were developed for use in manufacturing plants. If the enterprise has a discrete production type (Assembly to Order - ATO, Production to Order - MTO, Production to Warehouse - MTS, Serial - RPT), i.e. when there is a bill of materials and product composition for the manufactured products, then the use of the MRP system is logical and expedient. If the enterprise has a process production (Process Industry, Continuous-Batch Processing), then the use of MRP functionality is justified in the case of a long production cycle.

MRP systems are rarely used for planning material requirements in service, transport, trade and other organizations of a non-production profile, although potentially the ideas of MRP systems can, with some assumptions, be applied to non-production enterprises, whose activities require planning materials over a relatively long period of time.

MRP systems are based on material planning for the optimal organization of production and include directly the functionality for describing and planning the utilization of production capacities CRP (Capacity Resources Planning) and are aimed at creating optimal conditions for the implementation of the production plan for the release of products.

2. The main idea of the MRP system

The main idea of MRP systems is that any accounting unit

materials or components necessary for the production of the product must be available in the right time and in the right amount.

The main advantage of MRP systems is the formation of a sequence of production operations with materials and components, which ensures the timely manufacture of units (semi-finished products) for the implementation of the main production plan for the release of finished products.

3. Basic elements of MRP

The main elements of the MRP system can be divided into elements that provide information (software implementation of the algorithmic basis of MRP) and elements that represent the result of the functioning of the software implementation

Figure 1- Elements of the MRP system

In a simplified form, the following elements represent the initial information for the MRP system:

1) Master Production Schedule (MPP) - Master Production Schedule

The main production plan, as a rule, is formed to replenish the stock of finished goods or satisfy customer orders.

In practice, the development of PPEs appears to be a planning loop. Initially, a draft version is formed to assess the possibility of ensuring implementation in terms of material resources and capacities.

The MRP system provides detailed PPP in the context of material components. If the required nomenclature and its quantitative composition are not present in the free or previously ordered stock, or in case of unsatisfactory planned deliveries of materials and components, the PPP should be adjusted accordingly.

After carrying out the necessary iterations, the OPP is approved as valid and on its basis the production orders are launched.

2) Bill of materials and product composition

The bill of materials is a nomenclature list of materials and their quantities for the production of a certain assembly or final product. Together with the composition of the product, the bill of materials provides the formation of a complete list of finished products, the amount of materials and components for each product and a description of the structure of the product (nodes, parts, components, materials and their relationships).

The bill of materials and the composition of the product are database tables, the information of which correctly reflects the corresponding data, when the physical composition of the product changes, the state of the tables must be timely corrected.

3) Stock status

Current state stocks are reflected in the appropriate tables indicating all the necessary characteristics of accounting units. Each unit of account

regardless of the options for its use in one product or many finished products, it should have only one identifying record with a unique code. Typically, an account unit identification contains a large number of parameters and characteristics used by the MRP system, which can be classified as follows:

General data: code, description, type, size, weight, etc.

Stock data: stock unit, storage unit, free stock, optimal stock planned to order, ordered stock, distributed stock, batch / batch characteristic, etc.

Purchasing and sales data: purchase / sales unit, main supplier,

Production data and production orders, etc.

Accounting unit records are updated every time inventory transactions are performed, such as planned for purchase, ordered for delivery, capitalized, scrap, and so on.

Based on the input MRP data, the system performs the following basic operations:

Based on the PPP, the quantitative composition of the final products is determined for each planning time period;

Spare parts not included in the list are added to the finished products.

For OPP and spare parts, the total requirement for material resources is determined in accordance with the bill of materials and the composition of the product with distribution by planning time periods;

The total material requirement is adjusted based on the stock status for each planning time period;

The formation of orders for replenishment of stocks is carried out, taking into account the necessary lead times.

The results of the MRP system are:

Schedule of supply of material resources of production - the number of each accounting unit of materials and components for each period of time to ensure PPP. To implement the supply schedule, the system creates an order schedule based on time periods, which is used to place orders to suppliers of materials and components or for planning self-made;

Changes to the supply schedule plan - making adjustments to the previously formed production supply schedule;

A series of reports required to manage the supply chain of production.

One of the components of MRP-class integrated enterprise management information systems is a production capacity planning system

The main task of the CRP system is to check the feasibility of MPS in terms of equipment loading along production technological routes, taking into account the changeover time, forced downtime, subcontracting work, etc. Input information for CRP is a schedule of production orders and purchase orders for materials and components, which is converted in accordance with technological routes into the loading of equipment and workers.

Typical functionality of MRP systems:

Description of plan items and planning levels

Description of planning specifications

Formation of the main production plan of the schedule

Product management (description of materials, components and finished product units)

Inventory Management

Product configuration management (product composition)

Maintaining a bill of materials

Calculation of material requirements

Formation of MRP purchase orders

Generation of MRP transfer orders

Work centers (description of the structure of production work centers with the definition of capacity)

Machines and mechanisms (description of production equipment with the definition of standard capacity)

Manufacturing operations performed in relation to work centers and equipment

Technological routes representing a sequence of operations performed over time on a specific equipment in a specific work center

Calculation of capacity requirements to determine the critical load and make a decision

4.MRP II (Manufactory Resource Planning)

In the 1980s, the basic principles of MRP (Material Requirements Planning), CRP (Capacity Requirements Planning,

capacity demand planning), Closed Loop MRP (demand planning

in the materials in a closed cycle) were summarized into a single planning methodology - MRP II (Manufactory Resource Planning, production resource planning).

The Roman numeral "II" in the name of the new MRP II methodology arose due to the similarity of the abbreviations Manufactory Resource Planning and Material Requirements Planning, and

indicates a higher level of planning compared to Material Requirements Planning. Sometimes it is omitted if it is clear from the context which system is being discussed.

MRP II methodology describes end-to-end planning and chain management

"sales - production - warehouse - supply". Unlike previous planning methodologies, it focuses on operational planning and management of the entire production process, and not its individual fragments.

The MRP II methodology is aimed at solving the following main tasks:

1. Form the main production schedule (volumetric

schedule, Master Production Schedule - MPS), which schedules what and in what quantity the enterprise will produce in each period of the planning period. On the one hand, this plan should take into account as much as possible the existing portfolio of orders and marketing research of demand in order to meet the needs of customers in a timely manner, but also not to produce a surplus of products, which will subsequently lie in the warehouse for a long time, waiting for its buyer. On the other hand, the drawn up plan must be feasible given the current structure of the company's assets (production capacity, personnel, financial security). Achieving a compromise between meeting market demand and the feasibility of such a production program is a very important task, and it is successfully solved using the MRP II methodology.

2. Make operational plans that reveal the implementation of the approved production program: schedule production works, a schedule for the procurement of raw materials and supplies, a schedule for the use of funds. All production activities of the enterprise are subsequently built according to these plans. However, MRP II increases the value of these plans by the fact that within the framework of this methodology, an important task of optimizing resource consumption is solved. Namely, when drawing up plans, the goal is to optimally distribute consumed resources (money, materials, production capacities) throughout the entire planning segment. It is necessary, on the one hand, to ensure the fulfillment of the main production schedule and the continuity of the production process, and, on the other hand, to prevent the creation of excessive inventories. Achieving such a goal requires integrated planning of resource requirements, i.e., planning requirements at the level of all departments involved in the production process (production, warehouse, supply and sales), with consideration of a complex system of relationships between these departments.

The implementation of the MRP II methodology in a specific information system presupposes the presence of feedback informing about the quality of implementation of the formed plans and allowing, if necessary, to make adjustments to these plans.

The MRP II methodology was originally developed for assembly (discrete) manufacturing. Mechanical engineering is a classic example of discrete manufacturing. Without going into details, discrete manufacturing can be defined as: it is the production of assembling the final product, based on a hierarchical description of the composition of the product. Subsequently, similar principles and planning methods were developed for other types of production.

5. The logic of the MRP II-system focused on assembly (discrete) production

There are three distinct stages in the operation of the MRP II system. The first two involve the implementation of the MRP II methodology and end with the approval of plans. The latter, which proceeds in parallel with the real production process, includes monitoring the implementation of the plans formed and promptly, if necessary, making amendments to the production process:

Figure 2

1) Based on orders of independent demand, the main production schedule is formed.

· According to the data of the production plan, market research, forecast of demand, portfolio of orders for products, a preliminary schedule for the release of final products is drawn up.

· The RCCP (Rough Cut Capacity Planning) procedure is launched - a quick check of the feasibility of the drawn up plan in terms of the available capacity and the existing production technology. This procedure involves the creation of a flow of orders of dependent demand between the divisions of the enterprise involved in the production process, and checking the feasibility of these orders in pre-allocated critical areas of production (i.e., in work centers that limit or determine the shift release of products).

· If the preliminary schedule for the release of final products is recognized as feasible, then it becomes the main release plan. Otherwise, the preliminary schedule is modified and retested using the RCCP procedure.

2) Based on the accepted production schedule, the requirements for materials, capacities and financial resources are planned.

· The standard MRP cycle is started, the main result of which is the schedule of purchase / production orders for materials and components.

· A CRP cycle is launched, which gives a production work schedule describing all further production activities.

· According to these two documents, the need for finance (Financial Requirements Planning - FRP) for the implementation of production activities is estimated. That is, the operating costs for the purchase of materials, production needs, salaries for production personnel, etc. are calculated, and these costs are distributed over the entire planning horizon.

3) In accordance with the formed schedules, real production activities begin. At the same time, the MRP II-system carries out operational management of the production process: it monitors the implementation of planned tasks and, if necessary, makes adjustments to the existing plans.

· The fulfillment of the planned targets is promptly registered in the MRP II-system. The system, based on the comparison of actual and standard indicators, analyzes the course of the economic process. For example, to monitor the fulfillment of CRP plans, the MRP II system monitors the amount of productivity of each production unit throughout the planning period. The actual productivity is compared with the standard performance indicator and, if the deviation exceeds a predetermined allowable value, the system signals the management personnel to urgently intervene in the operation of this production unit and take measures to increase its productivity. Such measures can be, for example, attracting additional workers or increasing the standard working time of a lagging production unit. Likewise, the system monitors the consumption of materials and components by production units and registers the deviation of the actual and target consumption values for each production unit. This allows you to quickly diagnose a situation when a production unit does not develop planned productivity due to insufficient supply of materials.

· Analyzing the progress of the production process, the MRP II-system daily generates shift tasks for work centers (Operation lists), which are sent to the managers of work centers. Shift tasks reflect the sequence of working operations on raw materials and components at each unit of production capacity and the duration of these operations. In contrast to the production work schedule generated by the CRP-module, these workshop tasks automatically take into account the decrease / increase in the speed of the production

units: shift jobs can contain both production orders that are late for some reason (decrease in processing speed) and production orders planned for subsequent planning periods (increase in processing speed).

· In the same way, by forming adjusted daily tasks for the purchase / supply of raw materials and components, the MRP II-system regulates the work of the supply, sales and warehouse structures of the enterprise.

6. Development of MRP II: extension to "non-discrete" types of production

As noted above, the MRP II and MRP II systems were originally developed for assembly production. However, over 40% of industrial companies in the world are enterprises with a different type of production -

process.

According to the classification proposed by the Gartner Group, the whole variety of industries can be reduced to three main types:

1) design production;

2) discrete manufacturing;

3) process production.

Design production is a unique one-time production (for example, rocketry, shipbuilding), the technology of which is not predetermined.

The main distinguishing feature of discrete production is the presence of counting units of the output, which, in turn, is assembled from individual components. Therefore, in discrete manufacturing, the basis for the manufacture (assembly) of the final product is a hierarchical description of the composition of the product (that is, the design or production specification of the final product). A classic example of discrete manufacturing is mechanical engineering.

In discrete industries, there are several significantly different types of production organization:

· Manufacturing to a warehouse (Make-To-Stock - MTS): the volume of production is planned based on the "optimal utilization of production capacities"; in this case, it is assumed that all manufactured products will find sale;

Manufacturing to order (Make-To-Order - MTO): the volume of production is planned based on the received orders for products, and they are distinguished:

o development to order (Engineering-To-Order - ETO), when you have to start with the design of the ordered product, the development of design and technological documentation;

o assembly to order (Assembling-To-Order - ATO), in which design and technological documentation for various units already available at the enterprise is used, however, slight variability in the composition of the product is allowed, depending on the customer's order (in this case, all original components are assumed to be available on warehouse).

Process production consists of a number of technological processes (for example, mixing, dissolving, heating), each of which cannot be interrupted at any time. In addition to the final product, process manufacturing typically produces many by-products and ancillary products.

Technological process, as a rule, is divided into several stages, described by its recipe. The output of the same process can produce different products, depending, for example, on the concentration of the starting components, temperature regime, catalysts. Some processes can be repeated recursively (recycle).

Process industries are characterized by inextricable internal links between different types of products produced in the course of one process. For example, when oil is refined in one unit, petroleum products from gas oil and gasoline to fuel oil and bitumen are simultaneously obtained, and the composition of the products cannot be changed.

By the property of discreteness / continuity in time of release of the final product, among the process industries, repetitive ones are distinguished, respectively (for example, pharmacy, food industry, pulp and paper production, chemical industry) and continuous (for example, energy, oil and gas production, petrochemistry, primary metallurgy).

Each type of production has its own specific planning and management. If planning of discrete production proceeds from the volumetric indicators of production plans and a rigidly specified composition of the final product, then in design production they rely on a list of project activities and their interrelationships (that is, they make up the so-called network diagrams). In process industries, the first place is taken by the indicators of the utilization of production capacities and the variability of the technological process.

Originally developed for discrete manufacturing, the MRP II methodology did not meet the specifics of other types of manufacturing. Attempts to "correct" the underlying mathematical model for applications, for example, in process manufacturing, have led to unrealistic results such as negative production times and negative resource consumption. This approach did not become effective due to the fundamental differences between discrete and process industries. Therefore, for the process and design industries, original mathematical models and algorithms for solving the resource planning problem were created, which was the basis for the creation of MRP II-systems focused on "non-discrete" types of production.

Characteristic feature classic MRP II-systems is specialization in a specific (one or more) type of production. Recently, however, manufacturers of MRP II systems are modifying their products, expanding functionality, and transferring them to new platforms. This is due to the tough competition in the information management systems market, and, as a consequence, the desire to maximize customer satisfaction.

As a result of the evolution of MRP II systems, a new class of systems appeared (Enterprise Resource Planning, corporate resource planning).

7. Features of the implementation of MRP-II systems

Currently, in Russia, using MRP-II systems, they often try to replace outdated accounting or home-made information systems with a more powerful, modern and fashionable corporate resource management system of an enterprise.

It is not difficult to predict the results of such an implementation: after a year, two or three implementation, the system will work, but, as a rule, it will be worse than the old one. This is not surprising, since this is a different system, from which the same results are required as from the old one.

One of the foreign consultants commented on this situation as follows: “The MRP II class system is as effective as the personnel and business processes of the company are efficient. The fewer complications there are in these processes (which means fewer actions that do not ultimately increase the company's profit), the more effective the MRP-II system will be. Many companies have tried and are trying to describe their existing business processes using the implemented MRP-II class system. With this implementation, they simply “automate” the enterprise's current way of doing things without improving it in the least. Remember the golden rule: if you continue to work the way you worked, you will get what you got. ”

In the end, the implementation is recognized as unsuccessful and the system itself is blamed for the failure, or rather, the lack of the desired functionality in it.

Why? The answer is simple. Despite the fact that on Russian market there are many companies that will gladly sell the MRP-II system to the enterprise; successful implementation will not be possible without the hard work of the entire team of the enterprise. MRP-II is not a computer program. It is an enterprise management concept made possible by a computer. Because of this, the factors influencing the success or failure of the implementation of MRP-II systems depend largely on the efforts to implement the system. The experience of introducing MRP-II systems all over the world (Russia is no exception) suggests that, first of all, attention should be paid to the following points:

Linking implementation goals with enterprise goals;

Using a team approach;

Change management;

Training;

Attracting qualified consultants.

Implementation goals

Before starting planning a project for the implementation of the MRP-II system, first of all, it is necessary to formulate the global goals of the company, to determine where the company wants to come in a year, two, five or more. In accordance with this, you should plan the size of the company, the volume of sales in rubles and in kind, the number of personnel, the required equipment. The plan should contain sales volumes by product groups in value terms, information on how they will be produced, using only the capacity of the enterprise or otherwise, etc. These estimates will serve as the basis for working out the structure of an enterprise or group of enterprises, with the help of which and the set goals will be achieved. Then the goals should be determined at a more detailed level, after which it will already become possible to begin planning the resources necessary to ensure a given level of production. Next, you need to really assess the state of the enterprise today.

Based on the obtained basic information, it is necessary to determine the need for additional resources to ensure the growth of the company's turnover. Due to this, the future information system will make the management of the enterprise clearer, increase the efficiency of the organization, save resources and ultimately bring the business to a new level without attracting additional investments.

Team approach

Implementation of the MRP-II system requires significant efforts and resources of the enterprise. And it is the managers of the enterprise who must ensure the distribution of these resources: the general director (president) of the company, as well as the heads (directors) of the main divisions. Since systems of the MRP-II class are, as a rule, integrated systems, one of the typical results of their implementation is the following: departments that traditionally did not trust each other and competed for resources are forced to combine their efforts to ensure implementation goals. This is facilitated by the team approach used in the implementation of such systems.

Change management

The introduction of the MRP-II system and, accordingly, the change in the business processes of the enterprise can cause fear in a significant part of the staff of the enterprise. This is a natural fear of change, a reluctance to give up what, albeit bad, but worked in the past, and to accept the completely unknown and frightening new. The best way overcoming this fear is staff training. Only by understanding what exactly will be required of them in the future and what they will receive in return (for example, the work they have done will become more efficient, save jobs, the company will move to a new stage of development, etc.), will the personnel be able to work effectively in the project by changing methods and essence of the functioning of the enterprise and at the same time using necessary tools(knowledge). It is important to note that this is not so much about learning to work with an information system, but about general education: MRP-II concepts, change management, management accounting, etc.

Education

Introduction of any new equipment or information system requires training of personnel to interact with them, as well as the availability of appropriate support and support. That is, it is necessary to constantly train and improve the qualifications of personnel, improve or develop new procedures.

Use of consultants

The consultant will help set goals, plan implementation and project management, and provide staff training. A good consultant will squeeze out of the system as much as the company can use. But he will never take responsibility for the final results of the implementation. The enterprise and each of its employees must become the owner of the corresponding part of the system and take responsibility for its functioning.

Lecture 10. Resource planning systems enterprises -ERP(ERP, Enterprise Resource Planning)

General understanding of ERP. History of the emergence of ERP-systems Concept and functions of ERP-systems. Production: before the advent of ERP, with the advent of ERP. Implementation experience: advantages and disadvantages

05 01 medical biochemistry where to work

05 01 medical biochemistry where to work Biochemistry who can work

Biochemistry who can work Types of monopolies: natural, artificial, open, closed

Types of monopolies: natural, artificial, open, closed